How Window Air Conditioners Keep You Cool: A Breakdown Of The Refrigeration Process

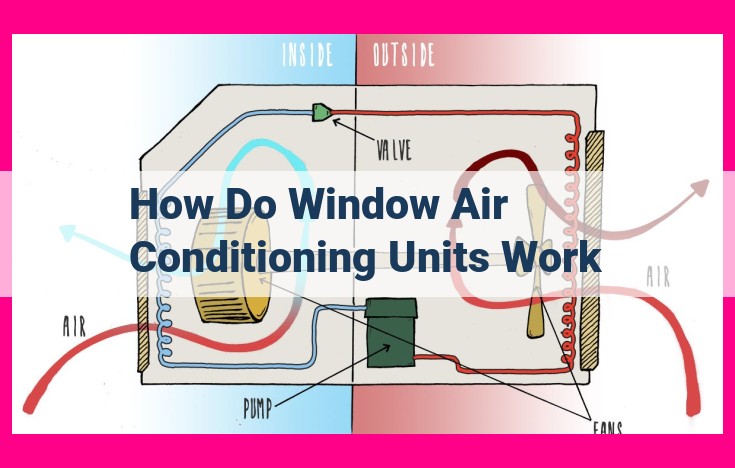

Window air conditioning units utilize refrigeration principles to cool indoor air. They consist of a compressor, condenser, expansion valve, evaporator, and refrigerant. The compressor compresses the refrigerant, which increases its pressure and temperature. The compressed refrigerant then flows through the condenser, where it cools and turns into a liquid. The liquid refrigerant then passes through the expansion valve, which lowers its pressure and temperature. This cooled liquid refrigerant circulates through the evaporator, where it absorbs heat from the warm indoor air, causing it to evaporate and cool the air. The evaporated refrigerant then returns to the compressor, and the cycle repeats.

From icy treats to chilled sodas, refrigeration has become an indispensable part of our modern lives. It preserves food, keeps environments comfortable, and even cools our computer servers. But how do these systems work their magic? Let’s delve into the fascinating world of refrigeration!

The Purpose and Significance of Refrigeration Systems

Refrigeration systems perform a critical function: removing heat from a medium, be it food, air, or equipment. This process not only preserves food by slowing down bacterial growth but also controls temperature in homes, offices, and data centers. Without refrigeration, our lives would be significantly less comfortable and nutritious.

Core Components of a Refrigeration System

When your refrigerator hums to life, it’s thanks to the intricate symphony of components that work together to keep your food fresh and your drinks cold. Let’s dive into the heart of these systems and explore the key players responsible for this cooling magic:

The Compressor:

Imagine a tiny heart pumping refrigerant through the system. That’s the compressor’s role. It compresses the refrigerant gas, raising its pressure and temperature, preparing it for the next step.

The Condenser Coil:

Think of the condenser coil as the cool kid on the block. It dissipates the heat from the compressed refrigerant. As the refrigerant flows through the coiled tubes, it releases heat to the surrounding air, like a releasing tension.

The Expansion Valve:

Now, let’s meet the regulator: the expansion valve. It controls the flow of refrigerant into the evaporator coil by regulating its pressure and flow rate. It’s like the traffic cop of the system, ensuring a steady stream of refrigerant.

The Evaporator Coil:

Here’s where the magic happens. The evaporator coil absorbs heat from the surrounding environment, such as the inside of your refrigerator. As the refrigerant passes through the coiled tubes, it expands and turns into a gas, drawing heat away from the area being cooled.

The Fan:

The fan is the unsung hero, quietly circulating air across the condenser and evaporator coils. It helps dissipate heat effectively, ensuring optimal cooling performance.

The Refrigerant:

The refrigerant is the lifeblood of the system. This specialized fluid changes between a liquid and a gas state, absorbing and releasing heat as it circulates. Common refrigerants include R-134a, R-410a, and R-600a.

Copper Tubing:

Copper tubing connects the various components, forming the intricate network through which the refrigerant flows. Its superior thermal conductivity ensures efficient heat transfer.

How Refrigeration Works: A Journey into Coolness

In the realm of modern convenience, few inventions rival the transformative power of refrigeration systems. They have revolutionized our lives, allowing us to preserve food, create refreshing air-conditioned environments, and maintain optimal temperatures for delicate electronics.

But have you ever wondered how these remarkable machines work their magic? Let’s delve into the inner workings of refrigeration systems and explore the intricate process that brings us coolness on demand.

The Refrigeration Cycle: A Continuous Loop of Heat Transfer

At the heart of refrigeration lies the refrigeration cycle, a continuous loop of heat transfer that extracts warmth from one area and releases it elsewhere. This cycle involves four key stages:

Compression: The Heartbeat of Cooling

The compressor, the powerhouse of the refrigeration system, compresses a refrigerant gas, increasing its pressure and temperature.

Condensation: Heat Dispersal

In the condenser coil, the hot, compressed refrigerant releases its heat into the surrounding environment, typically through air or water. This process condenses the refrigerant back into a liquid.

Expansion: The Key to Chilling

The expansion valve allows the high-pressure liquid refrigerant to rapidly expand, causing it to evaporate into a gas. This dramatic expansion absorbs heat from the surrounding area, resulting in a cooling effect.

Evaporation: The Cooling Exchange Zone

In the evaporator coil, the refrigerant gas absorbs heat from the air or liquid being cooled, causing it to evaporate further. This heat transfer process creates the chilling effect we rely on for food preservation, air conditioning, and other cooling applications.

Once the refrigerant has completed its journey through the evaporator coil, it returns to the compressor, and the cycle repeats, continuously removing heat from the desired area and redirecting it elsewhere.

Refrigeration Systems: Applications That Keep Us Cool and Comfortable

In today’s modern world, refrigeration systems are indispensable, playing a vital role in maintaining our comfort and preserving food. These systems find application in various settings, from our homes to commercial establishments and industrial facilities.

Residential Cooling: Refrigeration systems are the heart of our air conditioners, cooling our homes during hot summer days. They remove heat and humidity from the air, creating a comfortable and refreshing environment for us to relax and rest.

Commercial Cooling: Businesses and offices rely heavily on refrigeration systems to maintain a cool and productive work environment. These systems regulate the temperature in offices, retail stores, and restaurants, ensuring the well-being of employees and customers alike.

Server Room Cooling: As technology becomes increasingly prevalent, the need for reliable cooling solutions in server rooms has become paramount. Refrigeration systems are used to dissipate the heat generated by computers and other electronic equipment, preventing overheating and ensuring optimal performance.

Spot Cooling: In certain situations, spot cooling is necessary to cool specific areas within a larger space. For example, refrigeration systems are used in manufacturing facilities to cool workstations where workers are exposed to heat or in medical settings to provide localized cooling to patients.

**Maintaining Refrigeration Systems: A Guide to Keeping Your Unit Running Smoothly**

Maintaining your refrigeration system is crucial to ensure its longevity and efficiency. Regular care and maintenance can prevent costly repairs and extend the lifespan of your unit. Here’s a comprehensive guide to maintaining your refrigeration system:

**Air Filter Cleaning**

Dirty air filters can obstruct airflow, reducing the system’s cooling capacity. Regular cleaning is essential to prevent this. Check your air filters monthly and replace them when they become clogged.

**Coil Cleaning**

Condenser and evaporator coils accumulate dirt and debris over time, reducing heat transfer and efficiency. A thorough cleaning should be performed every 6-12 months by a qualified technician to ensure optimal performance.

**Refrigerant Charging**

Refrigerant is the lifeblood of your refrigeration system. It must be at the correct level to maintain proper cooling. Call a licensed technician for a refrigerant check and refill if needed.

**Electrical Inspections**

Electrical components can malfunction due to aging or loose connections. Regular inspections of wiring, capacitors, and other electrical connections are essential to prevent electrical fires or other hazards.

**Additional Tips for System Maintenance**

- Monitor Temperature: Keep an eye on the temperature of your refrigerator or freezer. If it’s not maintaining the desired temperature, it may indicate a problem.

- Avoid Overloading: Overloading your refrigeration unit can strain the compressor and reduce its lifespan. Organize items and allow for proper airflow.

- Regular Defrosting: If your refrigeration unit has a manual defrost feature, perform it regularly to prevent ice buildup on the evaporator coils.

- Check for Noises or Leaks: Any unusual noises or leaks should be investigated promptly by a qualified technician. Ignoring these signs can lead to more severe problems.

By adhering to these maintenance practices, you can ensure the smooth and efficient operation of your refrigeration system for years to come. A well-maintained refrigeration unit will not only provide optimal cooling but also save you money on energy costs and repair bills in the long run.

Controls and Monitoring for Refrigeration Systems

Staying in control of your refrigeration system is crucial for ensuring it operates at optimal efficiency and keeps your food and beverages fresh. Several essential components work together to monitor and manage the system’s performance:

Thermostats

Thermostats are the brains of your refrigeration system, constantly monitoring the temperature inside your unit and turning the compressor on and off as needed to maintain the desired temperature. Digital thermostats offer greater precision and control, allowing you to set specific temperatures for different compartments or zones within your unit.

Remote Controls

Remote controls provide convenience at your fingertips, allowing you to adjust the temperature or other settings without opening the refrigerator or freezer door. These controls typically connect to your unit wirelessly, giving you the freedom to make changes from anywhere in your home.

Air Vents

Air vents play a critical role in maintaining optimal airflow within your refrigeration system. They allow cold air to circulate throughout the unit, ensuring even cooling and preventing warm spots where food may spoil. Proper placement and unobstructed airflow around air vents are essential for efficient performance.

Other Monitoring Systems

In addition to thermostats, remote controls, and air vents, advanced refrigeration systems may incorporate other monitoring systems:

- Sensors: Sensors can detect changes in temperature, humidity, and other parameters, providing real-time data on the system’s performance.

- Data loggers: Data loggers record historical data on temperature and other variables, allowing you to track trends and identify any potential issues.

- Alarms: Alarms can be programmed to alert you to sudden temperature changes or other unusual conditions that may indicate a problem with the system.

Regularly monitoring and maintaining your refrigeration system’s controls and monitoring systems is essential for reliable operation and extended lifespan. By keeping these components in good working order, you can ensure that your food and beverages stay fresh and your system operates at peak efficiency.

Energy Efficiency in Refrigeration Systems: Maintaining Optimal Performance

When it comes to energy consumption, refrigeration systems play a significant role in both residential and commercial settings. Implementing strategies to enhance their energy efficiency is crucial to reduce operating costs and contribute to environmental sustainability.

Proper System Sizing

Selecting a refrigeration system with the appropriate capacity for your cooling needs is essential. An undersized unit will struggle to maintain desired temperatures, leading to excessive energy consumption. Conversely, an oversized unit will cycle on and off frequently, increasing energy waste.

Regular Maintenance

Regular maintenance is paramount for maintaining optimal energy efficiency. Clean air filters reduce airflow resistance, minimizing the energy required by the compressor. Clean coils ensure efficient heat transfer, preventing the system from working harder. Refrigerant levels should be checked and charged as needed to maintain optimal system performance.

Refrigerant Selection

The choice of refrigerant used in a refrigeration system can impact its energy consumption. Environmentally friendly refrigerants, such as R-410A and R-134a, have a lower global warming potential (GWP) and can improve energy efficiency.

Other Energy-Saving Measures

- Insulating cooling pipes can minimize heat loss and reduce energy consumption.

- Variable speed compressors adjust their speed based on cooling demand, saving energy during periods of lower usage.

- Occupancy sensors turn off cooling when a room is unoccupied, further reducing energy waste.

By implementing these strategies, you can improve the energy efficiency of your refrigeration system, resulting in lower operating costs, reduced environmental impact, and a more comfortable indoor environment.