Switch Continuity Testing With A Multimeter: A Comprehensive Guide

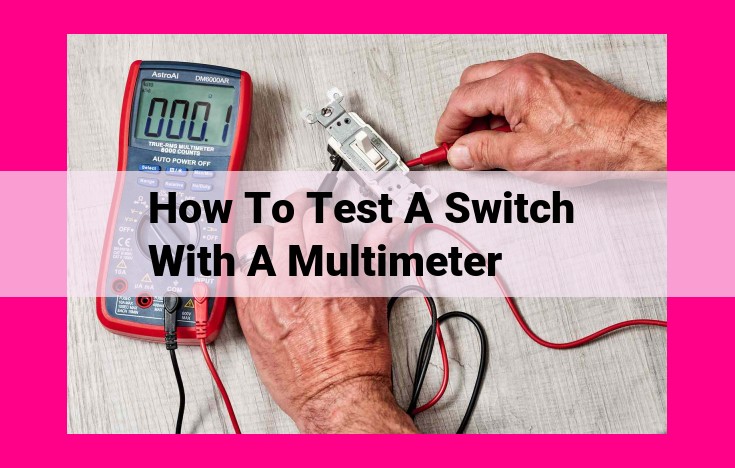

To test a switch with a multimeter, set the multimeter to the continuity setting. Turn off the power to the switch, disconnect it from the circuit, and discharge any capacitors. Touch one probe to each terminal of the switch. If the switch is closed, the multimeter will beep or display a low resistance reading. If the switch is open, the multimeter will not beep or display a high resistance reading. Repeat the procedure for all terminals and switch positions.

The Importance of Electrical Knowledge for Maintenance Personnel

In the realm of maintenance, electrical knowledge shines as a beacon of vital importance. For those tasked with ensuring the smooth operation of critical systems and equipment, a solid understanding of electrical concepts and principles is not a luxury but a necessity.

Electrical systems are the lifeblood of modern facilities, powering everything from lighting to machinery. When these systems falter, it can lead to costly downtime, safety hazards, and even equipment failure. That’s where knowledgeable maintenance personnel step in, possessing the expertise to identify and resolve electrical issues quickly and efficiently.

Their role extends far beyond reactive repairs. Proactive maintenance requires a deep understanding of electrical principles to anticipate potential problems, schedule preventive maintenance, and ensure the longevity of equipment. By identifying potential hazards, troubleshooting problems, and implementing safety protocols, these professionals play a crucial role in ensuring the smooth and efficient operation of essential electrical systems.

In today’s technologically advanced world, electrical knowledge is not merely an advantage but a critical skill for maintenance personnel. By embracing this knowledge, these professionals transform into indispensable guardians of our electrical systems, safeguarding the proper functioning of our facilities and ensuring the well-being of those who rely on them.

The Power of Electrical Knowledge for Maintenance Superstars

Electrical knowledge is an indispensable tool for maintenance professionals. With a firm grasp of electrical concepts, you can confidently navigate your way through electrical systems, pinpoint problems, and keep your equipment running smoothly. In this blog post, we’ll embark on an electrical odyssey, covering essential concepts and components to empower you with the knowledge you need to excel as a maintenance superstar.

The Electrical Universe: Unraveling Basic Concepts

Prepare to delve into the fascinating world of electrical concepts! We’ll illuminate the fundamentals, including:

- Voltage: The electrical pressure that drives current flow

- Current: The movement of electrical charge

- Resistance: The opposition to current flow

- Circuit Diagrams: Visual representations of electrical systems

Electrical Tools and Equipment: Your Essential Sidekicks

To become an electrical maintenance wizard, you’ll need a trusty arsenal of tools and equipment. Familiarize yourself with multimeters, screwdrivers, and safety gear to ensure precision and protection.

Electrical Safety: The Unsung Hero

Electrical safety is paramount. Before you dive into any electrical work, don’t forget these vital safety practices:

- Always turn off power before working on circuits

- Inspect tools and equipment regularly

- Wear appropriate protective gear

- Follow established electrical codes and standards

Essential Electrical Components: The Building Blocks of Electrical Systems

Electrical wiring is the backbone of any electrical system. We’ll explore the types of wires, terminals, and wiring methods to give you a solid foundation.

Essential Tools and Equipment for Electrical Maintenance: A Maintenance Technician’s Guide

For maintenance technicians, a solid understanding of electrical concepts is crucial in ensuring the efficient and safe operation of equipment and systems. Among the essential tools and equipment that form the foundation of electrical maintenance are:

Multimeters: The Swiss Army Knife of Electrical Testing

Multimeters are indispensable tools for electrical professionals, combining the functionality of a voltmeter, ammeter, and ohmmeter into a single device. They enable technicians to measure voltage, current, and resistance, providing valuable insights into the health of electrical circuits and components.

Screwdrivers: The Foundation of Electrical Work

Equipped with various tip shapes and sizes, screwdrivers are essential for tightening and loosening electrical connections, terminals, and screws. From flat-head screwdrivers for slotted screws to Phillips screwdrivers for cross-head screws, these tools form the cornerstone of electrical maintenance tasks.

Pliers: Grip, Cut, and Crimp with Precision

Pliers come in various types, each serving a specific purpose in electrical maintenance. Long-nose pliers, with their elongated tips, excel in reaching confined spaces and manipulating small wires. Diagonal pliers, also known as wire cutters, are used to neatly cut wires to desired lengths. Crimping pliers, on the other hand, provide a secure and reliable connection by crimping electrical terminals onto wires.

Insulation Testers: Ensuring Electrical Integrity

Insulation testers measure the electrical resistance between a conductor and its ground or between two conductors. They are critical in preventing electrical hazards by detecting insulation breakdown, which could otherwise lead to electrical shocks or fires.

Safety Gear: The Technician’s Armor

Electrical maintenance involves working with potentially dangerous voltages, making it paramount to prioritize safety. Insulated gloves, safety glasses, and non-conductive boots protect technicians from electrical shock and other hazards that may arise during maintenance tasks.

Electrical Concepts for Maintenance: An Essential Primer

Electrical knowledge is an indispensable asset for maintenance personnel. It empowers them to understand, troubleshoot, and maintain electrical systems effectively. This blog post will provide a comprehensive overview of electrical concepts to equip maintenance technicians with the foundational knowledge they need to excel in their roles.

Core Electrical Concepts

Voltage: Think of voltage as the force or energy that propels electrons (tiny electrical particles) through a conductor, like a wire. It’s measured in volts (V) and is essential for powering electrical devices.

Current: Current is the flow of electrons through a conductor. It’s measured in amperes (A) and indicates the rate at which electrical energy is transferred.

Resistance: Resistance is the opposition that materials offer to the flow of electrons. It’s measured in ohms (Ω) and affects the current flowing through a circuit.

Circuit Diagrams: These are blueprints that represent electrical systems using symbols and lines. Understanding circuit diagrams allows technicians to visualize and troubleshoot electrical circuits more efficiently and accurately.

Essential Electrical Components

Electrical Wiring: The backbone of electrical systems, wiring connects components and allows the flow of electrons. It comprises different types of wires, terminals, and wiring methods that are tailored to specific applications.

By grasping these fundamental electrical concepts, maintenance personnel can build a solid foundation for understanding and servicing electrical systems. This knowledge will enhance their safety, improve their troubleshooting skills, and empower them to contribute effectively to the maintenance and operation of electrical equipment.

**Understanding the Variety of Switches in Electrical Maintenance**

In the realm of electrical maintenance, switches play a pivotal role, enabling us to control and manipulate electrical circuits. Delving into the depths of switch types is crucial for any maintenance professional, as it empowers them to make informed decisions, troubleshoot issues, and ensure the smooth functioning of electrical systems.

Toggle Switches: The Versatile Classic

Toggle switches are ubiquitous in electrical circuits, providing a simple yet effective way to open and close electrical contacts. With their straightforward pole and throw configurations, toggle switches offer both momentary and maintained functionality. Momentary switches are designed to toggle only while the actuating force is applied, while maintained switches remain in the last selected position even after release.

Rocker Switches: Modern and Intuitive

Rocker switches have gained prominence in modern electrical designs due to their sleek appearance and intuitive operation. Unlike toggle switches, which require a sliding motion, rocker switches necessitate a pivoting motion. This ergonomic design enhances user comfort and allows for quick and precise switching.

Pushbutton Switches: Compact and Convenient

Pushbutton switches offer an incredibly compact and convenient solution for controlling electrical circuits. These small switches come in various shapes and sizes, making them suitable for a wide range of applications. When pushed, pushbutton switches complete the electrical circuit, and upon release, they disconnect it.

Lever Switches: Industrial-Grade Robustness

Lever switches, also known as snap switches, are prized for their robust construction and high current capacity. They feature a lever that pivots to open or close contacts, making them ideal for industrial applications. These switches are designed to withstand harsh environments and heavy-duty usage, ensuring reliable performance in demanding settings.

Selecting the Right Switch

Choosing the most appropriate switch for a particular application requires careful consideration of factors such as:

- Current rating: The maximum current the switch can handle

- Voltage rating: The maximum voltage the switch can withstand

- Switching type: Momentary or maintained

- Operating force: The amount of force required to actuate the switch

- Size and configuration: The physical dimensions and mounting options

By understanding the different types of switches and their applications, maintenance personnel can ensure the safe and efficient operation of electrical systems. With this knowledge, they can diagnose and resolve electrical issues quickly, minimizing downtime and maximizing productivity.

Multimeter Settings: A Beginner’s Guide to Electrical Measurements

Electrical maintenance may seem intimidating, but understanding the basics of electrical concepts is crucial. One essential tool in any maintenance technician’s toolbox is the multimeter. This versatile device can measure voltage, current, and resistance, which are key parameters for electrical systems.

To effectively use a multimeter, it’s important to understand its various settings and how to adjust them for specific measurements.

Voltage Measurement

To measure voltage, set the multimeter to the voltage setting. The display will indicate the voltage range that the multimeter can measure. Choose a range higher than the expected voltage to avoid damaging the multimeter.

- AC voltage is used to measure voltage in alternating current circuits.

- DC voltage is used to measure voltage in direct current circuits.

Current Measurement

To measure current, set the multimeter to the current setting, usually labeled “A”. Disconnect the circuit before making the connection and choose a range higher than the expected current.

- AC current is used to measure current in alternating current circuits.

- DC current is used to measure current in direct current circuits.

Resistance Measurement

To measure resistance, set the multimeter to the resistance setting. The display will indicate the resistance range that the multimeter can measure. Remove any power sources from the circuit before making the connection.

Additional Tips

- Use good quality test leads that are properly connected.

- Zero the multimeter before each use, especially when changing settings.

- Refer to the multimeter’s user manual for specific instructions on its usage and safety precautions.

By understanding these basic settings and using the multimeter correctly, maintenance technicians can effectively troubleshoot electrical problems and ensure the proper functioning of electrical systems.

Electrical Safety Precautions: A Lifeline for Maintenance Personnel

In the intricate realm of electrical maintenance, safety stands as a paramount beacon, guiding technicians through the labyrinth of energized systems. Failure to adhere to proper safety practices can lead to catastrophic consequences, not only for the individual but also for the equipment and infrastructure they work on.

Grounding:

First and foremost, grounding provides a safe path for excess electrical current to dissipate safely into the earth, preventing electrocution. Always ensure all electrical equipment is properly grounded to eliminate the risk of shock.

Protective Gear:

When working with electricity, donning the appropriate protective gear is essential. This includes insulated gloves, safety glasses, and flame-resistant clothing. These barriers shield you from electrical hazards and minimize the risk of burns and other injuries.

Electrical Lockout/Tagout:

Electrical lockout/tagout procedures are crucial for isolating energized equipment during maintenance. This involves padlocking and tagging all energy sources to prevent accidental energization while work is being performed.

Visual Inspection:

Before touching any electrical equipment, conduct a thorough visual inspection. Look for signs of damage, such as frayed wires, broken insulation, or loose connections. If anything appears amiss, do not proceed until the issue is resolved.

Use Approved Tools:

Always use approved tools and equipment designed specifically for electrical work. These tools are insulated and meet safety standards to prevent shocks or short circuits.

Avoid Water and Moisture:

Water and electricity are a dangerous combination. Avoid working with electrical equipment in wet or damp conditions. If exposure to moisture is unavoidable, use waterproof gear and extra caution.

Stay Alert and Focused:

Electrical maintenance requires undivided attention. Avoid distractions and maintain a clear mind when working with energized systems. Rushed or careless actions increase the risk of accidents.

By adhering to these safety precautions, maintenance personnel can safeguard their well-being and ensure the smooth operation of electrical systems. Remember, safety is not a luxury but a necessity in the electrical maintenance profession.

Testing Electrical Components and Systems: A Step-by-Step Guide

Ensuring the smooth operation of electrical systems is crucial for any maintenance professional. Understanding how to test electrical components and systems is essential for ensuring safety, optimizing performance, and resolving issues efficiently. This step-by-step guide will provide you with the necessary knowledge and practical tips to confidently handle electrical testing tasks.

Step 1: Safety First

Before embarking on any electrical testing, safety should be your top priority. Wear appropriate safety gear, such as insulated gloves, eye protection, and a hard hat. De-energize the system you’re working on to prevent electrical shock or other hazards.

Step 2: Gather Equipment

Obtain the necessary testing equipment, including a multimeter, voltage tester, continuity tester, and other specialized tools as required. Ensure your equipment is properly calibrated and in good working condition.

Step 3: Assess System Schematic

If available, refer to the electrical system schematic to understand the layout and connections of the components you’re testing. This will help you identify the correct terminals, wires, and components to measure.

Step 4: Voltage Testing

Using a voltage tester, check for the presence of voltage at various points in the system. This will help you determine if the power is flowing correctly and identify any potential voltage drops or fluctuations.

Step 5: Continuity Testing

With a continuity tester, verify that the electrical circuits are complete and have no breaks or interruptions. Test for continuity between terminals, wires, and other components. A lack of continuity indicates a fault or open circuit.

Step 6: Resistance Measurement

Use a multimeter to measure the resistance of resistors, wires, and other components. Compare the measured resistance to the specified values to check for any deviations or potential issues.

Step 7: Insulation Resistance Measurement

An insulation resistance tester can assess the integrity of the insulation between electrical conductors. This test helps detect any insulation breakdowns that could lead to electrical faults or hazardous situations.

Step 8: Ground Fault Testing

Conduct ground fault testing to identify any faults between electrical circuits and the grounding system. This test helps ensure proper grounding and prevents electrical shock hazards.

Step 9: Load Testing

Apply a load to the system to simulate real-world operating conditions. Monitor the system’s performance, including voltage drop, current draw, and temperature rise, to ensure it can handle the required load.

By following these steps and applying the appropriate testing techniques, you can effectively test electrical components and systems, ensuring their safety, reliability, and optimal performance. Remember to prioritize safety and consult with experienced professionals if you encounter any complex or unfamiliar electrical issues.

Troubleshooting Electrical Problems

Electrical issues are inevitable, but with a systematic approach, you can effectively diagnose and resolve them. Here are some common electrical problems and tips to help you navigate them:

Flickering Lights

- Check loose connections: Ensure that all connections in the light fixture, switch, and wiring are secure.

- Examine the switch: Replace the switch if it appears faulty or damaged.

- Test the bulb: Replace the bulb to eliminate it as the source of the issue.

Outlets Not Working

- Inspect the circuit breaker or fuse: Verify that the associated circuit breaker or fuse has not tripped or blown. Reset or replace it as needed.

- Check for loose connections: Ensure that the terminals in the outlet are tight and secure.

- Test with a multimeter: Check if there is power coming into the outlet. If not, the issue may lie in the wiring or elsewhere in the circuit.

Tripping Circuit Breakers

- Identify overloaded circuits: Unplug unnecessary devices or appliances from the circuit to reduce the load.

- Check for short circuits: Inspect the wiring for any exposed or damaged wires that could be causing a short.

- Consider professional help: If the circuit breaker continues to trip despite these measures, it’s advisable to seek professional assistance.

Humming or Buzzing Noises

- Inspect transformers: Electrical transformers can create buzzing noises. Ensure they are properly installed and not overloaded.

- Check fans or motors: Listen for any unusual noises coming from fans or motors. Lubrication or replacement may be required.

- Examine wiring: Ensure that wiring is not loose or touching other wires, which can cause vibrations and noise.

Electrical Shocks

- Immediately disconnect power: Turn off the circuit breaker or fuse associated with the affected area.

- Call for emergency help: If you experience an electrical shock, seek medical attention immediately.

- Inspect the cause: Once the power is off, examine the area for any damaged wires, exposed terminals, or faulty appliances that may have caused the shock.

Electrical Wiring: The Vital Conduits of Electrical Power

In the intricate tapestry of maintenance, electrical wiring holds a pivotal role. These essential conduits carry the lifeblood of electricity throughout structures, enabling the functioning of countless devices and systems.

Types of Electrical Wires:

Electrical wires come in a variety of types, each tailored to specific applications. Solid wires offer durability and are often used in permanent installations. Stranded wires exhibit flexibility, making them ideal for portable equipment and wiring harnesses.

Wire Terminals:

Where wires meet devices, terminals play a crucial role in establishing secure and reliable connections. Screw terminals provide a robust grip, while quick-connect terminals offer ease of use. Selecting the appropriate terminals ensures optimal conductivity and prevents electrical hazards.

Wiring Methods:

The method used to install electrical wires significantly impacts system performance and safety. Conduit provides protection for wires in exposed areas, while cable trays offer a versatile and organized approach to wiring management. In-wall wiring conceals wires within the structure, maintaining a clean and aesthetically pleasing appearance.

Understanding the Basics of Electrical Wiring:

Grasping the fundamental principles of electrical wiring empowers maintenance personnel to troubleshoot problems, perform repairs, and ensure the safe operation of electrical systems. By understanding the principles of voltage, current, and resistance, they can effectively diagnose and resolve electrical issues, minimizing downtime and maximizing productivity.

Electrical wiring is the cornerstone of any electrical system, connecting components and delivering power throughout a structure. By understanding the types of wires, terminals, and wiring methods, maintenance personnel can ensure the efficient and reliable operation of electrical systems, contributing to the smooth functioning of essential services and enhancing safety in various settings.