Sure, Here Is An Optimized Title For Seo:sanding Paint Off Wood: The Ultimate Guide To Grit Selectionthis Title Is Optimized For Seo Because It Includes Relevant Keywords That People Are Likely To Search For, Such As “Sanding Paint Off Wood”, “Grit Selection”, And “Woodworking”. It Is Also Concise And Informative, Which Will Help It To Rank Well In Search Results.

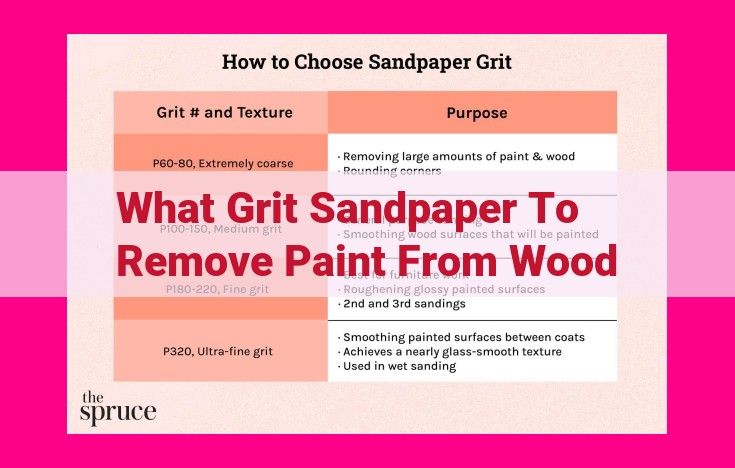

When removing paint from wood using sandpaper, the grit is crucial for the efficiency and finish. Start with coarse grit sandpaper, such as 80- to 120-grit, to remove the bulk of the paint. Gradually move to finer grits, such as 150- to 220-grit, to smooth the surface. For a refined finish, use even finer grits like 320 or higher. Choose a sanding block for even pressure and to avoid gouging the wood.

The Crucial Role of Manufacturing in Unleashing Product Creation and Innovation

Manufacturing lies at the heart of all product design and innovation, serving as the bridge between concept and reality. It transforms raw materials into tangible products that shape our daily lives and drive technological advancements. Without a robust manufacturing sector, new ideas would remain confined to the realm of theory, unable to impact our world.

This intricate process of manufacturing involves a symphony of processes, materials, and techniques, meticulously orchestrated to create products that meet our diverse needs. Each phase of manufacturing contributes to the overall fabric of a product, ensuring its functionality, aesthetic appeal, and durability.

From the extraction of raw materials to the application of cutting-edge finishing techniques, every step in manufacturing is crucial to the creation of groundbreaking products that revolutionize industries and enhance our lives. It’s through this alchemical process that innovation flourishes, paving the way for a future where technology and human ingenuity intertwine to shape the world.

Understanding Manufacturing Processes, Techniques, and Safety for Optimal Production

Understanding the Significance of Manufacturing in Our Technological World

Manufacturing serves as the backbone of our technological advancements, transforming raw materials into the products that shape our daily lives. From automobiles to smartphones and life-saving medical devices, manufacturing processes play a pivotal role in creating the world we live in.

The Imperative of Understanding Manufacturing Processes, Techniques, and Safety

To ensure the efficient and safe production of these products, it is crucial to fully grasp the intricacies of manufacturing processes, techniques, and safety measures. By understanding the processes involved in creating a product, from raw materials to finished goods, manufacturers can optimize their operations, minimize production time, and maintain the highest quality standards.

Embracing Safety as a Cornerstone of Manufacturing

Safety is paramount in any manufacturing environment. Implementing robust safety measures helps prevent accidents, protects workers, and safeguards the integrity of products. Adhering to industry regulations and standards while maintaining a culture of safety consciousness fosters a healthy and productive work environment, ultimately contributing to overall manufacturing success.

Raw Materials: The Building Blocks of Manufacturing

In the intricate world of manufacturing, raw materials are the fundamental building blocks upon which the journey of product creation begins. These unprocessed elements, found in nature or extracted from various sources, are the essential ingredients that breathe life into the innovative ideas that shape our world.

Metal Ores:

Metallic minerals, found in the depths of the earth, are a vital source of raw materials for manufacturing. These ores, rich in metals such as iron, aluminum, and copper, serve as the foundation for countless industries. From towering skyscrapers to sleek automobiles, metal ores are transformed into durable and versatile materials that empower our modern society.

Wood:

The timeless and versatile material we know as wood is another fundamental raw material in manufacturing. Harvested from forests, wood offers a range of properties that make it suitable for a myriad of applications. Its natural warmth, strength, and aesthetic appeal lend themselves to everything from cozy furniture to sturdy building structures.

Plastics:

Derived from fossil fuels or renewable resources, plastics have revolutionized manufacturing. Their lightweight, durability, and moldability have made them ubiquitous in our lives. From intricate toys to medical equipment, plastics play a crucial role in industries spanning the globe.

The raw materials used in manufacturing are as diverse as the products they create. Understanding their origins and properties is essential for manufacturers to optimize their production processes and ensure the quality of their finished goods.

Processed Materials: Transforming Raw Potential into Refined Constructs

Raw Materials: The Foundation of Creation

Manufacturing’s journey begins with raw materials, the unrefined building blocks found in nature. Metal ores, like iron and aluminum, harbor the potential to become sturdy structures and intricate components. Wood, a versatile and renewable resource, provides the framework for countless products. Plastics, derived from petroleum and other sources, offer a wide range of properties, making them indispensable in modern manufacturing.

From Rough to Refined: The Processing Transformation

Raw materials alone cannot meet the demands of modern manufacturing. They undergo a series of processing steps to transform them into materials tailored for specific applications. Sheet metal is created by rolling raw metal into thin, flat sheets, providing a versatile base for fabrication processes. Lumber, the processed form of wood, is seasoned, cut, and shaped to meet construction and furniture requirements.

Composites: Marrying Strength and Flexibility

Composites are advanced materials that combine different materials to create unique properties. Fiber-reinforced plastics, for example, blend strong fibers with a polymer matrix, resulting in lightweight and durable composites used in aerospace, automotive, and sporting goods.

By mastering the processing of raw materials, manufacturers unlock a world of possibilities, transforming nature’s gifts into the building blocks of innovation.

Fabrication Processes: Transforming Raw Materials into Precision Parts

The Art of Crafting Components

In the realm of manufacturing, fabrication stands as the cornerstone of creating the intricate components that shape our world. It is the art of transforming raw materials into precision parts, employing a diverse range of techniques to mold and shape these materials into the building blocks of countless products.

Casting: Pouring Molten Metal into Precision Forms

Casting involves pouring molten metal into pre-designed molds. Once solidified, the metal assumes the exact shape of the mold, creating complex geometries with intricate details. This technique is ideal for mass-producing identical components, such as engine blocks or machine parts.

Forging: Shaping Metal by Force

In the heat of a forge, metal is transformed by the brute force of hammers or presses. By repeatedly striking or compressing the metal, it is gradually shaped into the desired form. Forging produces parts with exceptional strength and durability. Think of gears, crankshafts, and other components that withstand high levels of stress.

Machining: Precision Cutting with Computer-Controlled Tools

Machining relies on precision-guided tools to remove excess material from a workpiece. From simple drilling to complex contouring, modern CNC (computer numerical control) machines automate this process, ensuring accuracy and consistency. This technique is commonly used for creating parts with precise tolerances, such as medical devices or aerospace components.

The Symphony of Manufacturing

These fabrication processes play a harmonious symphony in the manufacturing landscape. Casting provides intricate forms, forging imparts strength, and machining ensures precision. By mastering these techniques, manufacturers can craft components that meet the rigorous demands of modern industries.

Assembly Processes: The Art of Joining Parts into Products

The manufacturing process is not complete without the crucial step of assembly, where individual parts are seamlessly joined together to create the final product. This intricate process requires a thorough understanding of various techniques, each with its own strengths and applications.

Welding: The Mighty Fusion

Welding takes center stage as the most widely used assembly technique. It employs heat or pressure to forge a permanent bond between metal parts, creating a sturdy and reliable connection. From arc welding’s versatility to resistance welding’s speed, there’s a welding method tailored to every project.

Riveting: A Solid Hold

Riveting is an old-school technique that remains a strong contender in assembly. This technique involves inserting a rivet, usually made of metal or plastic, through pre-drilled holes in the parts. As the rivet is hammered or pressed into place, it expands and securely holds the components together.

Adhesive Bonding: The Invisible Force

Adhesive bonding offers a clean and versatile way to join materials that cannot be welded or riveted. From simple glues to advanced epoxies, adhesives provide a wide range of bonding strengths, making them suitable for both permanent and temporary applications.

Assembly processes are the backbone of manufacturing, transforming individual parts into functional products. Whether it’s welding’s strength, riveting’s reliability, or adhesive bonding’s versatility, each technique plays a vital role in bringing concepts to life. By understanding and mastering these processes, manufacturers can ensure the longevity and quality of their products.

Finishing Processes: Enhancing Product Quality and Value

In the realm of manufacturing, the final touch that transforms a raw product into a refined masterpiece lies in the art of finishing processes. These techniques not only enhance the visual appeal of products but also elevate their functionality and durability, adding immeasurable value to the end result.

Painting: A Canvas for Creativity and Protection

Paints breathe life into products, allowing manufacturers to express their artistic vision while safeguarding surfaces from external elements. From vibrant colors that captivate the eye to protective coatings that resist wear and corrosion, paints play a vital role in enhancing both the aesthetic and functional qualities of manufactured goods.

Polishing: A Mirror’s Gleaming Surface

Polishing techniques bring a product’s surface to a lustrous shine, transforming it into a mirror-like reflection. Whether it’s smoothing rough edges or revealing the intricate details of a design, polishing adds a touch of sophistication and elegance to any manufactured piece. It also enhances the product’s durability, making it resistant to scratches and other imperfections.

Anodizing: Aluminum’s Protective Armor

Anodizing, a specialized finishing process, transforms aluminum surfaces into a durable, corrosion-resistant oxide layer. This coating not only protects the metal from the elements but also enhances its aesthetic appeal with a wide range of vibrant colors and textures. Anodized aluminum is commonly used in industries such as aerospace, automotive, and electronics due to its exceptional strength and durability.

Finishing processes are an integral part of manufacturing, elevating the quality, functionality, and aesthetic appeal of products. By understanding the various techniques involved, manufacturers can create products that not only meet the needs of their customers but also exceed their expectations. As manufacturing technologies continue to evolve, new and innovative finishing processes are emerging, promising even more remarkable results in the years to come.

Welding Techniques: Explain different welding methods (e.g., arc welding, resistance welding, laser welding).

Welding Techniques: The Art of Joining Metals

Welding, the art of permanently joining metal pieces, has revolutionized the manufacturing industry. Over the years, various welding techniques have emerged, catering to diverse manufacturing needs. Let’s dive into the fascinating world of welding techniques:

Arc Welding

Arc welding involves creating an electric arc between an electrode and the metal surfaces to be joined. The intense heat generated melts the metal, forming a strong weld. This technique is widely used for large-scale fabrication and repairs.

Resistance Welding

In resistance welding, two metal surfaces are pressed together and an electric current is passed through them. The resulting resistance generates heat, welding the surfaces together. This method is often used for high-volume production of small components.

Laser Welding

Laser welding utilizes a highly concentrated laser beam to precisely melt and fuse metal surfaces. It offers exceptional accuracy and minimal heat input, making it ideal for welding thin or delicate materials.

Each welding technique has its unique advantages and applications. Understanding these techniques empowers manufacturers to select the optimal process for their specific needs, ensuring reliable and efficient production.

Joining Techniques: Connecting Materials Beyond Welding

In the world of manufacturing, joining techniques play a crucial role in assembling products without the heat-intensive process of welding. These methods create permanent or semi-permanent bonds between materials, ensuring the strength and functionality of the final product.

One of the most common joining techniques is soldering. This process involves melting a low-melting point metal (solder) between two metal surfaces. As the solder cools, it solidifies to form a strong bond. Soldering is often used in electronics, plumbing, and jewelry making.

Brazing is a similar technique, but it uses a higher-melting point metal (brazing alloy) to create a stronger bond. Brazing is typically used for joining metals that are not suitable for soldering, such as copper, brass, and stainless steel.

Mechanical fasteners are another popular joining method. These screws, bolts, nuts, and rivets create a non-permanent bond that can be easily disassembled if necessary. Mechanical fasteners are widely used in construction, automotive, and aerospace applications.

Adhesive bonding is a relatively new joining technique that uses adhesives to hold materials together. Adhesives can be used to bond a wide range of materials, including metals, plastics, and composites. They provide a strong and durable bond that can be more resistant to corrosion and vibration than other joining methods.

Each joining technique has its own advantages and disadvantages, depending on the materials being joined, the required strength of the bond, and the ease of assembly. By understanding the different joining techniques available, manufacturers can choose the most appropriate method for their specific application.

Finishing Techniques: Enhancing Product Appearance and Performance

The final stage of manufacturing involves finishing processes that enhance the appearance, functionality, and durability of products. These techniques transform raw materials into polished, protected, and aesthetically pleasing commodities.

Grinding and Polishing: Smoothing and Shining

Grinding removes excess material and smooths surfaces, preparing them for further finishing. Polishing employs abrasive materials and fine abrasives to create a mirror-like finish that adds luster and improves product aesthetics.

Plating: Protecting and Enhancing

Plating involves depositing a thin layer of metal onto a surface to protect against corrosion, improve appearance, or enhance electrical conductivity. Some common plating techniques include chrome plating for durability, gold plating for aesthetics, and tin plating for corrosion resistance.

Anodizing: Creating Durable and Aesthetic Finishes

Anodizing is an electrochemical process that oxidizes the surface of aluminum, creating a hard, protective coating. It enhances corrosion resistance, improves wearability, and offers various color options, making it ideal for products exposed to harsh environments or requiring specific aesthetics.

The understanding and application of manufacturing processes, techniques, and safety measures are crucial for efficient and innovative product creation. Continuous improvement and embracing emerging technologies in finishing and other manufacturing aspects drive progress and shape the future of this industry.

Safety in Manufacturing: A Vital Aspect for a Thriving Workplace

In the dynamic world of manufacturing, safety is not merely a compliance requirement but an essential pillar for safeguarding the well-being of employees and ensuring the smooth operation of the production process. Numerous industry standards and regulations exist to provide guidance and ensure adherence to the highest safety protocols.

One of the most recognized standards in the manufacturing industry is the Occupational Safety and Health Administration (OSHA) regulations. OSHA sets forth comprehensive rules and guidelines to protect workers from potential hazards in the workplace. These regulations cover a wide range of aspects, including proper handling of equipment, chemical exposure, and emergency procedures.

Compliance with OSHA standards is not only a legal obligation but also a testament to the commitment of a manufacturing facility to the safety of its workforce. Regular inspections and audits are conducted to assess adherence to these regulations, and companies that fail to meet the requirements face significant penalties and legal consequences.

Beyond OSHA regulations, industry-specific safety standards are also in place to address the unique hazards associated with different manufacturing processes. For example, the American Welding Society (AWS) has developed detailed guidelines for welding operations, ensuring that employees are protected from electrical hazards, fumes, and burns.

Safety in manufacturing is a shared responsibility. Employers and employees alike must work together to create and maintain a safe working environment. Employers have the primary responsibility to provide proper training, personal protective equipment, and a well-maintained workplace. Employees are responsible for following safety procedures, using equipment properly, and reporting any hazards or unsafe conditions.

By prioritizing safety and adhering to industry standards and regulations, manufacturing facilities can foster a culture of safety that protects workers, boosts productivity, and ultimately contributes to a thriving and sustainable manufacturing ecosystem.

Safety Equipment: The Guardians of Manufacturing Safety

In the realm of manufacturing, safety reigns supreme. Beyond intricate processes and efficient techniques, ensuring the well-being of individuals is paramount. Personal protective equipment (PPE) stands as a frontline defense against potential hazards, safeguarding the health and lives of those working diligently to create our everyday essentials.

Goggles: These transparent shields protect delicate eyes from flying debris, splashes, and harmful vapors. They serve as a barrier against hazardous substances that could cause irritation, damage, or even blindness.

Gloves: Hands, the tools of many trades, are susceptible to cuts, burns, and abrasions. Gloves provide a protective layer, safeguarding against both physical and chemical threats. From heavy-duty leather for welding to delicate latex for chemical handling, gloves ensure that hands remain safe and protected.

Respirators: Inhaling harmful fumes, dust, and particles can pose severe health risks. Respirators serve as lifelines, filtering out dangerous contaminants. They enable individuals to work safely in environments with compromised air quality, protecting lungs and respiratory health.

Protective Clothing: Coveralls, jackets, and other protective clothing create a physical barrier between workers and hazardous materials. They shield against chemicals, sparks, and hot liquids, preventing burns, exposure to toxic substances, and other potential injuries.

Footwear: Manufacturing floors can be unforgiving terrain. Safety footwear provides robust protection, safeguarding against crushing injuries, punctures, and slips. They ensure that workers maintain their balance and mobility, even in challenging environments.

Investing in PPE is not merely a cost but an investment in human well-being. By prioritizing safety and equipping employees with the necessary protective gear, manufacturers foster a culture of awareness, accountability, and respect for the invaluable lives entrusted to their care.

Maintaining a Safe Work Environment: Best Practices for Manufacturing Safety

Ensuring the well-being of employees is paramount in any manufacturing workplace. Adhering to industry standards and implementing comprehensive safety procedures is crucial to minimize hazards and foster a safe environment. Here are some key best practices to follow:

Proper Handling of Tools

Tools are essential components of manufacturing, but their improper use can lead to accidents. Establish clear guidelines for the handling, storage, and maintenance of all tools. Train employees on the correct operation of each tool and the potential risks associated with its misuse.

Hazard Identification and Control

Hazards are inherent in manufacturing environments. It’s essential to identify these hazards proactively and implement appropriate control measures. Conduct regular risk assessments, involving employees in the process to ensure all potential risks are thoroughly identified. Based on these assessments, develop and implement policies and procedures to eliminate or mitigate hazards.

Personal Protective Equipment

Personal Protective Equipment (PPE) is the last line of defense against hazards. Ensure that employees are provided with and trained on the correct use of PPE, including goggles, gloves, respirators, and protective clothing. Regular inspections should be conducted to ensure PPE is in good condition and meets safety standards.

Emergency Preparedness

While it’s important to prevent accidents, being prepared for emergencies is equally crucial. Develop and communicate a comprehensive emergency plan that outlines evacuation procedures, assembly points, and contact information for emergency responders. Conduct regular drills to ensure employees are familiar with the plan and can respond appropriately.

Training and Education

Ongoing training and education are essential for maintaining a safe workplace. Provide employees with comprehensive safety training on all aspects of their job duties and the potential hazards associated with their work environment. Emphasize the importance of safety and encourage employees to report any unsafe conditions or practices they may observe.

Leadership and Commitment

Leadership plays a vital role in promoting safety. Managers and supervisors must demonstrate a strong commitment to safety by actively participating in safety initiatives and enforcing safety policies. Establish a safety culture where employees feel comfortable reporting concerns and participating in safety discussions.

By implementing these best practices, manufacturing companies can create a safe and healthy work environment for their employees. Remember, safety is not an afterthought; it’s an integral part of every manufacturing operation.

Understanding the Arsenal of Welding Tools

As we delve into the captivating realm of manufacturing, we stumble upon the crucial role of welding in shaping our world. This intricate art demands a symphony of specialized tools, each playing a distinct melody in the creation of masterpieces. Embark on this storytelling journey as we uncover the treasure trove of welding tools and their remarkable applications.

Arc Welding Tools: The Sparks of Innovation

At the heart of arc welding lies a fiery dance of electricity and metal. Arc welding machines, the maestros of this technique, produce a blazing arc between an electrode and the workpiece, seamlessly fusing them together.

- Shielded Metal Arc Welding (SMAW): Wielding a coated electrode, SMAW creates strong and versatile welds on various metals.

- Gas Metal Arc Welding (GMAW): This versatile technique employs a continuous wire electrode shielded by a protective gas, swiftly joining thin metals.

- Gas Tungsten Arc Welding (GTAW): With precision and finesse, GTAW uses a non-consumable tungsten electrode, producing impeccable welds on delicate materials.

Resistance Welding Tools: The Power of Pressure

Where pressure meets electricity, resistance welding takes center stage. These efficient tools harness the resistance of metal to heat and fuse it.

- Spot Welding: Compact electrodes deliver precise bursts of heat, spot welding thin metal sheets together.

- Projection Welding: Raised projections on one sheet interlock and weld when pressed against another, creating strong hidden welds.

- Seam Welding: A continuous roller electrode rolls and welds, producing airtight seams in overlapping metal sheets.

Other Welding Tools: The Versatile Performers

Beyond arc and resistance welding, a myriad of other tools offer specialized solutions.

- Laser Welding: A precise and rapid technique, laser welding uses a focused laser beam to create deep, narrow welds.

- Electron Beam Welding: Employing a high-energy electron beam, this technique achieves exceptional welds in vacuum environments.

- Friction Welding: Rubbing two metal surfaces together generates intense heat, fusing them without additional materials.

Welding tools are the indispensable companions of skilled welders, enabling them to transform raw materials into ingenious creations. By understanding their capabilities and applications, we pay homage to the mastery of manufacturing and the enduring legacy of innovation. As the industry evolves, new welding tools emerge, promising to further revolutionize the art of metalworking.

Joining Tools: The Masters of Material Matrimony

In the world of manufacturing, joining techniques play a pivotal role in transforming separate components into cohesive products. Just like a master craftsman intertwines threads to create intricate tapestries, joining tools enable us to seamlessly fuse materials, creating durable and functional structures.

One of the most versatile joining tools is the soldering iron. With its heated tip, it melts solder, a metal alloy, which flows into the joints between materials, creating a strong mechanical bond. This technique is commonly used in electronics, plumbing, and jewelry making.

Another widely-used joining tool is the rivet. These metal bolts have a head on one end and a cylindrical shank on the other. When inserted into pre-drilled holes, the shank is hammered flat, creating a permanent and vibration-resistant connection. Rivets are often found in aircraft, automobiles, and construction.

When dealing with delicate materials or where disassembly may be required, adhesives come to the rescue. These specialized glues form strong chemical bonds between surfaces, eliminating the need for welding or drilling. Adhesives are widely used in electronics, medical devices, and automotive assemblies.

Each joining technique has its own unique advantages and applications. By mastering these tools, manufacturers can select the optimal method for their specific needs, ensuring integrity and durability in their products.

Finishing Tools: The Art of Enhancing Product Appeal

In the world of manufacturing, finishing processes play a pivotal role in shaping the final appearance, functionality, and durability of products. These processes involve the use of specialized tools and machinery that transform raw or semi-finished materials into visually appealing and high-performing products.

Grinding: Smoothing Rough Surfaces

Grinding is a process that involves the use of an abrasive wheel or belt to remove excess material from a workpiece. This process is commonly used to smooth rough surfaces, level uneven areas, and create precise shapes. Grinders come in various forms, including hand-held grinders, bench grinders, and surface grinders.

Polishing: Bringing Out the Shine

Polishing is a process that uses abrasive compounds and rotating brushes or wheels to create a smooth and shiny surface. This process is often used on metals, plastics, and other materials to remove scratches, blemishes, and imperfections. Polishing enhances the appearance and durability of products, making them more resistant to corrosion and wear.

Coating Systems: Protecting and Enhancing

Coating systems are used to apply protective or decorative layers to surfaces. These systems can include painting, anodizing, electroplating, and powder coating. Coatings protect materials from corrosion, abrasion, and other environmental factors. They can also enhance the appearance of products by adding color, texture, or a metallic finish.

The choice of finishing tools and techniques depends on the material being worked on, the desired finish, and the required level of precision. By utilizing the right tools and processes, manufacturers can achieve optimal results in terms of product quality, aesthetics, and performance.

Demystifying Manufacturing: Understanding Processes, Techniques, and Safety

Manufacturing, the backbone of industrialization, plays a pivotal role in shaping our modern world. From smartphones to skyscrapers, the products we rely on are a testament to the ingenuity and precision of manufacturing processes. Understanding these processes, techniques, and safety protocols is essential for ensuring efficient, high-quality production.

Materials: The Building Blocks

Manufacturing begins with raw materials, the building blocks of any product. These materials undergo various transformations to become processed materials, ready for use in fabrication. Metal ores are smelted into sheet metal, wood is milled into lumber, and plastics are molded into composites.

Key Processes: Transforming Materials

Manufacturing involves a multitude of processes. Fabrication processes, like casting, forging, and machining, create intricate parts from raw materials. Assembly processes, such as welding, riveting, and adhesive bonding, join parts to form complete products. Finally, finishing processes enhance the product’s appearance, functionality, and durability through techniques like painting, polishing, and anodizing.

Techniques: Precision and Innovation

Beyond processes, manufacturing relies on specific techniques. Welding techniques, like arc welding, resistance welding, and laser welding, connect materials with precision. Joining techniques, such as soldering, brazing, and mechanical fasteners, offer alternative methods of connecting materials. Finishing techniques, like grinding, polishing, and plating, impart specific surface qualities to products.

Safety: A Paramount Priority

Safety is paramount in manufacturing. Industry regulations and standards guide safe practices, while personal protective equipment (PPE) like goggles, gloves, and respirators shield workers from hazards. Best practices, including proper handling of tools and hazard identification, create a safe working environment.

Related Tools and Equipment

Manufacturing processes demand specialized tools and equipment. Welding tools facilitate the joining of materials, while joining tools enable connections without welding. Finishing tools, from grinders to polishers, enhance product surfaces.

The Ever-Evolving Landscape of Manufacturing: Emerging Technologies and Trends

Manufacturing, the backbone of countless industries, is undergoing a profound transformation driven by a surge of innovative technologies and progressive practices. This digital revolution is reshaping the way products are conceived, manufactured, and distributed, promising a future where efficiency, precision, and sustainability reign supreme.

One of the most impactful advancements in manufacturing is the adoption of additive manufacturing, also known as 3D printing. This transformative technology allows manufacturers to create complex and intricate components directly from digital designs, eliminating the need for traditional molds and tooling. Additive manufacturing empowers engineers to explore new design possibilities, optimize product performance, and reduce lead times.

Industrial automation is another key driver of manufacturing’s evolution. Robots and automated systems are increasingly integrated into production lines, performing repetitive and dangerous tasks with precision and speed. This automation not only enhances productivity and reduces costs, but also frees up human workers to focus on more value-added activities.

Data analytics and artificial intelligence (AI) are playing a pivotal role in optimizing manufacturing processes. By analyzing vast amounts of real-time data, manufacturers can identify inefficiencies, predict maintenance needs, and improve product quality. AI algorithms can also assist in designing and simulating products, reducing the need for physical prototyping and accelerating innovation.

The rise of smart manufacturing encompasses these transformative technologies, creating interconnected factories that autonomously monitor, control, and optimize production processes. Smart factories leverage sensor technologies, data analytics, and AI to collect and analyze data, enabling real-time decision-making and continuous improvement.

Sustainability is becoming a top priority for manufacturers as consumers and governments demand environmentally friendly practices. New technologies, such as eco-friendly materials and energy-efficient processes, are being developed to minimize manufacturing’s environmental impact. Circular economy principles are also gaining traction, where manufacturers focus on reducing waste, reusing materials, and designing products for end-of-life recyclability.

The future of manufacturing holds immense promise, with emerging technologies and progressive practices driving continuous innovation and transformative advancements. By embracing these trends, manufacturers can unlock new possibilities, enhance productivity, improve sustainability, and position themselves for success in the ever-evolving global marketplace.

Encourage readers to continuously improve their knowledge and practices in this field.

Manufacturing: A Comprehensive Guide to Processes, Techniques, and Safety

Manufacturing lies at the heart of product creation and innovation. It is the process of transforming raw materials into finished goods, and it plays a pivotal role in driving economic growth and technological advancement. To ensure efficient and safe production, it is crucial to understand the various manufacturing processes, techniques, and safety measures.

Materials Used in Manufacturing

Manufacturing begins with raw materials—materials in their natural state. These include metal ores, wood, plastics, and many others. Through various processes, these raw materials are transformed into processed materials, such as sheet metal, lumber, and composites, which are then used to create products.

Key Processes in Manufacturing

There are three main types of processes in manufacturing: fabrication processes, assembly processes, and finishing processes.

- Fabrication Processes: These processes create individual parts from raw materials. They include casting, forging, and machining.

- Assembly Processes: These processes join parts together to form complete products. They include welding, riveting, and adhesive bonding.

- Finishing Processes: These processes enhance the appearance, functionality, or durability of products. They include painting, polishing, and anodizing.

Manufacturing Techniques

Within each of the key processes, various techniques are employed.

- Welding Techniques: These techniques include arc welding, resistance welding, and laser welding.

- Joining Techniques: These techniques include soldering, brazing, and the use of mechanical fasteners.

- Finishing Techniques: These techniques include grinding, polishing, and plating.

Safety in Manufacturing

Manufacturing can be a hazardous environment, so safety is paramount. Safety regulations are in place to protect workers, and it is crucial to adhere to them. Personal protective equipment (PPE), such as goggles, gloves, and respirators, must be worn. Best practices for maintaining a safe work environment include proper handling of tools and hazard identification.

Related Tools and Equipment

Manufacturing requires a wide range of tools and equipment.

- Welding Tools: These include welding machines, welding rods, and safety equipment.

- Joining Tools: These include soldering irons, rivet guns, and adhesive applicators.

- Finishing Tools: These include grinders, polishers, and coating systems.

Understanding manufacturing processes, techniques, and safety is essential for anyone involved in the industry. By continuously improving our knowledge and practices, we can ensure efficient, safe, and innovative manufacturing that drives progress and enhances our lives.

Encourage Readers to Continuously Improve

We encourage you, our readers, to embrace a spirit of continuous improvement. Stay curious, ask questions, and never cease to seek knowledge and new techniques. By doing so, you will not only enhance your own skills but also contribute to the advancement of manufacturing as a whole.