The Art Of Potato Blanching: Optimizing Quality For Freezing, Canning, And Frying

Blanching Potatoes

Blanching potatoes involves a controlled heat treatment that prepares them for subsequent processing. It helps remove starch and enzymes that could cause discoloration or texture changes during storage or cooking. By briefly immersing potatoes in boiling water, steaming, or microwaving, blanching inactivates enzymes and preserves nutrients while preventing browning and softening. It optimizes potato quality for freezing, canning, or frying by enhancing texture, flavor, and shelf life.

Blanching: Preserving the Goodness of Your Favorite Foods

Blanching, the controlled application of heat to fruits, vegetables, or meat, is an essential step in food preservation. It not only enhances the flavor and texture of your food but also inhibits the growth of harmful microorganisms, ensuring your food stays fresh and safe for longer.

Why Blanch?

Blanching plays a crucial role in food processing by:

- Inactivating enzymes: Enzymes are naturally occurring substances that can cause deterioration of food. Blanching stops their activity, preserving the food’s freshness and quality.

- Removing undesirable gases: Blanching helps remove gases from the food, which can cause spoilage and affect texture. This results in improved flavor and appearance.

- Preparing for further processing: Blanching is a necessary step before freezing, canning, or frying. It helps reduce the volume of the food, making it easier to package and process.

Importance of blanching in food preservation

Blanching: A Vital Step in Food Preservation

In the art of culinary preservation, blanching stands as a technique of paramount importance, a safeguard that ensures the longevity and wholesome quality of our favorite foods. It’s a process that involves submerging food in boiling water or exposing it to steam for a brief period, a technique that seemingly transforms the ordinary into the extraordinary.

Blanching is a versatile tool that serves multiple purposes. Firstly, it halts enzymatic activity, which can cause food to ripen prematurely or degrade. By inhibiting these processes, blanching helps preserve the freshness and nutritional value of foods.

Furthermore, blanching plays a crucial role in removing surface contaminants and eliminating microorganisms that could pose health risks or compromise the quality of the food. It effectively cleanses the food, rendering it safe for consumption and storage.

Blanching also prepares food for subsequent preservation methods, such as freezing, canning, or frying. It helps maintain the integrity of the food’s texture, color, and flavor, ensuring that it retains its appeal and nutritional value even after being subjected to these processes. In essence, blanching acts as a culinary guardian, protecting our food from spoilage and preserving its freshness and flavor, allowing us to enjoy the bounty of nature’s gifts for longer.

Blanching: A Crucial Step in Food Preservation

When it comes to preserving the freshness and quality of fruits, vegetables, and other foods, blanching is an essential process that plays a vital role in maintaining their nutritional value, flavor, and texture. In this blog post, we will dive into the world of blanching, exploring its purpose, methods, and the variety of equipment used to achieve optimal results.

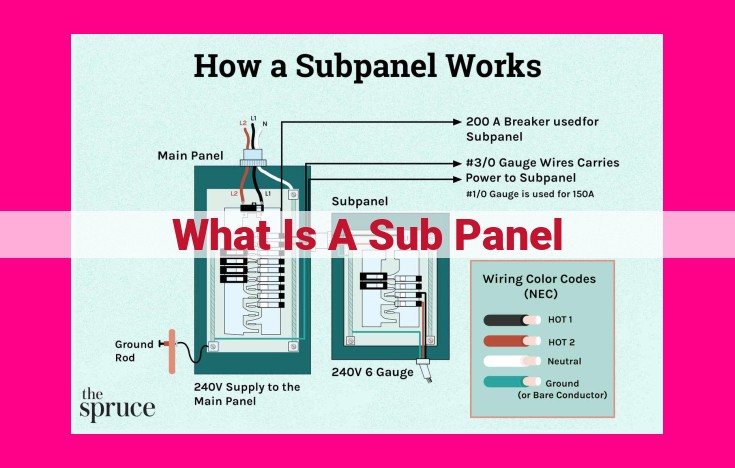

Types of Blanchers: A Versatile Trio

The primary equipment used in blanching falls into three main categories:

-

Boiling Water Bath: This classic method involves submerging food items in a cauldron of boiling water. Its simplicity and affordability make it a popular choice for small-scale operations.

-

Steam Blancher: Utilizing steam to blanch foods, this method provides gentle and uniform heat distribution, preserving the delicate texture and flavor of produce.

-

Microwave Blancher: A more modern approach, microwave blanching uses electromagnetic radiation to heat foods rapidly. This method offers precise control over temperature and timing, ensuring consistent results.

Advantages and Disadvantages: Weighing the Options

Each blancher type has its own set of pros and cons:

Boiling Water Bath:

- Advantages: Inexpensive, simple to operate

- Disadvantages: Can lead to overcooking on the outside while undercooking the inside, potential for nutrient loss

Steam Blancher:

- Advantages: Uniform heating, preserves texture and flavor, reduces nutrient loss

- Disadvantages: More expensive, requires careful monitoring of steam temperature

Microwave Blancher:

- Advantages: Precise temperature control, rapid blanching, energy-efficient

- Disadvantages: Can be more expensive, potential for uneven heating if not used properly

Blanching Processes and Equipment: A Comprehensive Guide

Blanching, a crucial process in food preservation, plays a vital role in ensuring the safety and quality of our favorite foods. This article delves into the world of blanching, exploring the different types of blanchers, their advantages and disadvantages, and the factors that influence effective blanching.

1. Blanching Equipment

Blanchers come in various types, each with its own set of strengths and weaknesses.

Boiling Water Baths:

- Pros: Simple and inexpensive, provides uniform blanching

- Cons: Requires large volumes of water, potential for water contamination

Steamers:

- Pros: Preserves nutrients, reduces water usage

- Cons: Can create uneven blanching, requires specialized equipment

Microwaves:

- Pros: Rapid and energy-efficient

- Cons: Potential for uneven heating, difficult to control temperature

2. Choosing the Right Blancher

The choice of blancher depends on the specific food being processed and the desired outcome. For instance, boiling water baths are ideal for products that are easily damaged by heat, such as delicate fruits and vegetables. Steamers are preferred for vegetables that need to retain their color and flavor, while microwaves are best suited for small-scale operations and products that require rapid blanching.

3. Factors Influencing Blanching

To achieve optimal blanching results, several factors must be considered:

- Water Temperature: The optimal temperature range varies based on the product, but generally falls between 82°C (180°F) and 100°C (212°F). Higher temperatures can overcook the food, while lower temperatures may not inactivate enzymes effectively.

- Blanching Time: The duration of blanching depends on the size, texture, and density of the food. Over-blanching can result in nutrient loss and mushy texture, while under-blanching can leave enzymes active and compromise safety.

- Product Characteristics: Different foods have varying resistances to blanching. Potatoes, for example, are more resistant than green beans, which require shorter blanching times.

- Potato Size: Larger potatoes require longer blanching times to ensure uniform inactivation of enzymes throughout the product.

Blanching Processes and Equipment: A Comprehensive Guide

Blanching: An Essential Step in Food Preservation

Blanching, by immersing food in boiling water or steam, plays a pivotal role in preserving its quality and extending its shelf life. By inactivating enzymes responsible for deterioration, blanching preserves flavor, color, and texture.

Optimal Blanching Temperature: Striking a Delicate Balance

The temperature range for blanching varies depending on the food item. The optimal temperature aims to:

- Inhibit enzymes effectively: Higher temperatures accelerate enzyme inactivation.

- Minimize nutrient loss: Excessive heat can leach valuable nutrients from the food.

- Preserve color and texture: Extended exposure to high temperatures can compromise appearance and texture.

For instance, potatoes require a blanching temperature between 175-190°F (80-88°C). This range effectively inhibits deterioration while preserving their natural qualities.

Implications of Blanching Time

The duration of blanching significantly impacts the blanching process. Over-blanching can lead to nutrient loss, loss of firmness, and darkened color. Conversely, under-blanching may not sufficiently inhibit enzyme activity, reducing the effectiveness of the process.

Blanching time varies based on factors such as:

- The type of food

- Maturity and size of the produce

- The equipment used

For example, potatoes require a blanching time of 3-5 minutes, while more delicate vegetables like spinach may only need 1-2 minutes.

Understanding the optimal blanching temperature and time is crucial for preserving food quality and safety. By tailoring these parameters to the specific needs of different foods, manufacturers can ensure maximum preservation while minimizing nutrient loss and maintaining desirable characteristics.

**Blanching: Preserving the Goodness of Fruits and Vegetables**

When it comes to preserving the freshness and quality of your produce, blanching is a culinary technique that deserves a spot in your kitchen repertoire. Blanching involves the brief immersion of fruits or vegetables in boiling water or steam, followed by immediate cooling in ice water. This seemingly simple process holds immense significance in the preservation of food.

The duration of blanching is a crucial factor that impacts the enzyme inactivation, color preservation, and nutrient retention of your produce. Too short a blanching time may result in insufficient enzyme activity inhibition, while excessive blanching can lead to nutrient degradation and textural changes.

The optimal blanching time varies depending on the type of produce, its maturity, and its size. For example, leafy greens like spinach require a shorter blanching time than root vegetables like potatoes. The size of the produce also plays a role, with larger pieces requiring longer blanching times.

Understanding the impact of blanching time on product quality is essential for achieving the desired results. By carefully tailoring the duration of blanching to the specific produce and its intended use, you can ensure that your fruits and vegetables retain their nutritional value, vibrant colors, and optimal texture.

So, the next time you’re preparing your produce for preservation, don’t underestimate the power of blanching. By mastering the art of controlling blanching time, you can extend the shelf life of your fruits and vegetables while preserving their natural goodness.

Blanching Processes and Equipment

Blanching is an essential step in food preservation, and it plays a crucial role in the potato processing industry. One important factor to consider during blanching is the resistance of different potato varieties to blanching.

Potato Varieties and Blanching Resistance

Different potato varieties exhibit varying levels of resistance to blanching. This resistance is primarily determined by the potato’s starch content and cell wall structure. Varieties with higher starch content tend to be more resistant to blanching, while those with lower starch content blanch more easily.

Starch Content and Cell Wall Structure

Starch content influences the firmness of potato tissue. Potatoes with higher starch content retain their firmness during blanching, while those with lower starch content become softer. This difference in firmness affects the blanching time required to achieve the desired level of enzyme inactivation.

Cell wall structure also plays a role in blanching resistance. Potatoes with thick cell walls are more resistant to blanching compared to those with thin cell walls. Thick cell walls create a barrier that slows down the penetration of heat and enzymes.

Practical Implications for Blanching

Understanding the blanching resistance of different potato varieties is crucial for optimizing the blanching process. Varieties with higher resistance require longer blanching times or higher blanching temperatures to achieve the desired results. Conversely, varieties with lower resistance can be blanched using shorter times or lower temperatures.

By adjusting the blanching conditions based on the potato variety, processors can ensure effective enzyme inactivation, color preservation, and texture retention. This, in turn, contributes to the overall quality and shelf life of frozen, canned, or fried potato products.

The resistance of different potato varieties to blanching is an important factor to consider in the blanching process. By understanding the influence of starch content and cell wall structure, processors can tailor their blanching parameters to achieve optimal results for specific varieties. This optimization leads to improved product quality, reduced processing time, and increased efficiency in the potato processing industry.

Potato Size: Impact on Blanching Effectiveness

Blanching, a crucial step in food preservation, involves submerging food products in boiling water or steam to inhibit enzyme activity and improve product quality. In the case of potatoes, potato size plays a significant role in determining the effectiveness of the blanching process.

Larger potatoes require longer blanching times to ensure uniform heat penetration. This is because heat transfer occurs more slowly in larger objects. Inadequate blanching can lead to enzymatic browning, softening, and nutrient loss. Conversely, over-blanching can result in nutrient leaching and texture loss.

Optimizing blanching time for different potato sizes is essential. Smaller potatoes, such as fingerlings, blanch more quickly than larger varieties, like russets. Blanching time should be adjusted accordingly to prevent under- or over-blanching.

For instance, small fingerling potatoes may require only 2-3 minutes of blanching, while larger russets may need 5-7 minutes. Consult industry guidelines or conduct trial runs to determine the optimal blanching time for specific potato varieties and sizes.

By considering potato size, food processors can tailor their blanching processes to ensure optimal product quality, safety, and nutritional value.

Heat Transfer: The Mechanism Behind Blanching

When we blanch vegetables, we are essentially submerging them in hot water or steaming them for a short amount of time. This process kills bacteria, inactivates enzymes, and softens vegetable tissue, making them more suitable for preservation.

But how exactly does heat transfer happen during blanching? Let’s explore the mechanisms:

1. Convection

Convection is the transfer of heat through the movement of a fluid. In the case of blanching, the fluid is water or steam. When the vegetable is placed in the hot water or steam, the hotter fluid rises, creating a convection current. This current transfers heat from the fluid to the surface of the vegetable.

2. Conduction

Conduction is the transfer of heat through direct contact. Once the heat reaches the surface of the vegetable, it is conducted into the vegetable’s interior. This heat spreads from the outer layer to the inner layer, gradually raising the temperature of the vegetable.

3. Latent Heat

When water is heated, it absorbs energy and converts into steam. This energy is known as latent heat. As the steam makes contact with the vegetable’s surface, it releases its latent heat, providing an additional source of heat transfer. This process vaporizes moisture from the vegetable, which intensifies the heat transfer.

By understanding these mechanisms, we can optimize the blanching process to ensure even heating, enzyme inactivation, and preservation of the vegetable’s nutritional value and quality.

Blanching: Preserving Food’s Goodness

Enzymatic Activity: Blanching’s Secret Weapon

As the gentle heat of the blanching process envelops your vegetables, it embarks on a culinary mission: to silence the symphony of enzymes that would otherwise rob them of their vibrant hues, nutrients, and delectable flavors. These tiny biochemical maestros, responsible for nature’s relentless ripening and decay, meet their match in the controlled environment of the blancher.

Blanching acts like a temporary “off switch” for enzymes, effectively putting their frenzied activity on hold. This strategic pause preserves the vegetables’ peak freshness and nutritional integrity, allowing them to endure the rigors of storage and cooking without compromising their culinary excellence. By deactivating enzymes, blanching ensures that your vegetables remain brimming with their natural goodness.

Imagine a vibrant carrot, its deep orange hue a testament to its rich beta-carotene content. Without blanching, enzymes would eagerly feast upon this precious pigment, leaving the carrot pale and lackluster. But in the blancher’s embrace, the enzymes’ appetite is curbed, preserving the carrot’s captivating color and nutrient-rich essence.

Likewise, delicate green beans, blanched to a crisp-tender perfection, owe their verdant hue to blanching’s enzyme-inhibiting magic. The chlorophyll that paints them a vibrant green would otherwise fade under the onslaught of uncontrolled enzymatic reactions, robbing them of their eye-catching beauty and health-promoting properties.

Blanching’s enzyme-silencing prowess not only safeguards the visual appeal of vegetables but also extends their shelf life. Enzymes left unchecked would accelerate the ripening and decay process, causing vegetables to wilt, lose flavor, and become more susceptible to spoilage. Blanching halts this relentless march, allowing you to savor the freshness and flavor of your produce for days or even weeks to come.

Moreover, blanching can enhance the nutritional value of certain vegetables by breaking down their complex carbohydrates, making them more readily digestible. It also facilitates the leaching of water-soluble vitamins and minerals into the blanching liquid, which can be captured and utilized in soups, sauces, or gravies, maximizing your nutritional intake.

So, next time you blanch your vegetables, know that you’re not just preparing them for further culinary adventures but also preserving their nutritional value and extending their shelf life. It’s a simple yet profound technique that pays dividends in terms of taste, health, and culinary versatility.

Chlorophyll Degradation: The Green Pigment’s Transformation Under Blanching

As we delve into the world of blanching, a crucial step in food preservation, there’s one aspect that stands out: the fascinating effect on chlorophyll, the green pigment responsible for plants’ vibrant color. Blanching, with its controlled heat treatment, plays a key role in altering chlorophyll’s composition, paving the way for remarkable changes in food quality.

The Miracle of Heat Transfer

During blanching, heat skillfully penetrates food tissues, inactivating enzymes that would otherwise cause deterioration. This enzymatic shutdown extends shelf life and preserves the nutritional goodness of our culinary creations. As heat invades these tissues, it also affects chlorophyll, the green pigment that gives vegetables their characteristic color.

Chlorophyll, delicately perched within the plant’s cells, undergoes a transformation under the influence of blanching’s heat. The chlorophyll molecules begin to break down, their intricate structures disassembling into smaller components. This process, aptly termed chlorophyll degradation, leads to a gradual fading of the green hue, revealing the vibrant colors hidden beneath.

Shades of Green Transformed

The extent of chlorophyll degradation depends on several factors, including the type of vegetable being blanched, the temperature of the blanching bath, and the duration of the heat treatment. For instance, vegetables with higher chlorophyll content, such as spinach or green beans, tend to lose their vibrant green color more rapidly than those with lower chlorophyll content, like carrots or potatoes.

As the blanching process unfolds, the chlorophyll degradation dance continues. The chlorophylls a and b, the predominant forms of chlorophyll in plants, break down at different rates, creating a shifting kaleidoscope of colors. The chlorophyll a gracefully surrenders its green embrace first, while chlorophyll b clings to its verdant charm a bit longer.

Culinary Symphony of Flavors and Colors

The blanching-induced chlorophyll degradation not only alters the visual appeal of vegetables but also has a profound impact on their flavor and nutritional value. Blanching preserves the delicate flavors, preventing the development of off-flavors that could mar the culinary experience. Additionally, blanching enhances the absorption of nutrients, making the vegetables more nutritious and beneficial for our health.

In conclusion, the process of chlorophyll degradation during blanching is a symphony of scientific and culinary artistry. It is a testament to the delicate balance between preserving the bounty of nature and preparing it for our enjoyment. By understanding the intricacies of this process, we can harness the power of blanching to unlock the full potential of our culinary creations, savoring their vibrant colors, delectable flavors, and nutritional abundance.

Blanching: The Key to Preserving Food Quality and Flavor

Blanching is a critical step in food preservation, transforming fresh produce into culinary masterpieces that can be enjoyed year-round. Its significance extends beyond its role in preparation for freezing, canning, and frying, as it unlocks a myriad of benefits that ensure the safety, quality, and flavor of our food.

When it comes to freezing, blanching plays a pivotal role in preserving the color, texture, and nutritional value of fruits and vegetables. By inactivating enzymes that would otherwise cause spoilage, blanching allows produce to retain its freshness and flavor for extended periods.

Similarly, blanching is essential for canning. By removing air and killing microorganisms, it creates an airtight seal that prevents spoilage and contamination. The blanching process also softens the produce, making it easier to pack and reduce the likelihood of breakage during handling.

Blanching shines in the realm of frying as well. By removing excess moisture, it promotes even cooking and prevents splattering. This results in crispier, tastier fried foods that retain their texture and flavor without becoming soggy.

In essence, blanching is the culinary alchemist that transforms ordinary produce into culinary treasures. It safeguards the nutritional integrity of our food, extends its shelf life, and elevates its flavor, ensuring that the joy of fresh food can be savored throughout the year.

Blanching: A Vital Step in Food Preservation

Blanching is a crucial process in food preservation that involves exposing food to boiling water or steam for a short period. This technique has several important benefits, making it an indispensable step in various food processing applications.

Specific Benefits of Blanching

-

Freezing: Blanching helps preserve the quality and nutritional value of fruits and vegetables during freezing. It slows down enzymatic reactions that can cause spoilage and reduce vitamin loss.

-

Canning: Blanching removes air from vegetable tissues, ensuring a longer shelf life in sealed cans. It also softens tissues for easier canning and reduces the risk of spoilage due to microorganism growth.

-

Frying: Blanching partially cooks vegetables and reduces their water content. This allows them to absorb less oil during frying, resulting in crispier and healthier fried foods.

Mechanism of Blanching

Blanching works by inactivating enzymes that can cause spoilage and reduce the level of chlorophyll in leafy vegetables, improving their appearance. It also removes surface dirt and microorganisms, making the food safer for consumption.

Blanching is a versatile technique with numerous benefits in food preservation. By inactivating enzymes, reducing chlorophyll, and removing contaminants, blanching helps extend the shelf life, maintain nutritional value, and improve the overall quality of food products. Its role in freezing, canning, and frying makes it an essential step in the food industry.

Parboiling: Pre-cooking potatoes to improve blanching efficiency

Blanching: A Vital Process for Preserving Freshness and Quality

In the world of food preservation, blanching stands out as a fundamental process that ensures the freshness, quality, and safety of our beloved fruits and vegetables. Blanching refers to the pre-treatment of food by exposing it to a controlled amount of heat, typically using boiling water or steam. This process serves multiple crucial purposes:

-

Enzyme Inactivation: Blanching effectively inactivates enzymes that cause spoilage and deterioration, thereby extending the shelf life of produce.

-

Microbial Reduction: It reduces the population of microorganisms, such as bacteria and molds, which can compromise food safety and quality.

-

Color and Nutrient Retention: Blanching preserves the vibrant color of vegetables, such as green peas and broccoli, by inhibiting chlorophyll degradation. Additionally, it helps retain essential nutrients, including vitamins and minerals.

-

Texture Modification: The heat treatment of blanching alters the texture of produce, making it softer and more tender. This is particularly important for vegetables like carrots and potatoes, which require a certain level of softness for processing and consumption.

Parboiling: Enhancing Blanching Efficiency for Potatoes

Potatoes, a staple food in many cuisines, present a unique challenge in the blanching process due to their variable starch content and resistance to heat penetration. To overcome this, food processors often employ a technique called parboiling. Parboiling involves pre-cooking potatoes in boiling water for a short duration, usually around 5-10 minutes.

This pre-treatment serves two primary functions:

-

Starch Gelatinization: Parboiling initiates the gelatinization of starch granules within the potato, making them more susceptible to heat penetration during subsequent blanching.

-

Water Absorption: The pre-cooking process allows potatoes to absorb water, creating a more uniform distribution of moisture throughout the produce, further enhancing the blanching process.

By incorporating parboiling into the blanching process, food processors can achieve more efficient and effective blanching, ensuring optimal quality, color, and texture in their potato products.

Blanching Processes and Equipment: A Comprehensive Guide

Blanching: Preserving Freshness and Quality

Blanching, an indispensable step in food preservation, involves subjecting fruits and vegetables to controlled heat treatment to enhance their shelf life and maintain their nutritional value. This process not only deactivates enzymes that can cause deterioration but also brightens colors, sets textures, and removes surface contaminants.

Choosing the Right Blanching Equipment

Selecting the appropriate blanching equipment is crucial for optimal results. Boiling water baths, steamers, and microwave blanchers are commonly used. Each type offers unique advantages and drawbacks, so it’s essential to consider the specific application requirements.

Key Variables Affecting Blanching

To achieve optimal blanching outcomes, it’s important to carefully control variables such as temperature, time, and potato variety. Temperature plays a critical role in enzyme inactivation and heat penetration, while blanching time impacts the desired texture and color preservation. The choice of potato variety also influences resistance to blanching, necessitating adjustments in time and temperature settings.

Scientific Principles of Blanching

During blanching, heat transfer occurs through conduction, convection, and radiation, ensuring uniform heating throughout the product. This heat deactivates enzymes responsible for undesirable changes, such as enzymatic browning and texture softening. Moreover, blanching aids in chlorophyll degradation, leading to the vibrant green color associated with fresh vegetables.

Practical Applications of Blanching

Blanching is extensively employed in food processing industries, particularly in preparation for freezing, canning, and frying. For freezing, blanching prevents deterioration and loss of nutrients during storage. In canning, it expels air from plant tissues, reducing the risk of spoilage and improving heat penetration during processing. Blanching also enhances the oil absorption of potatoes during frying, resulting in crispier textures.

Related Terminology

To enhance your understanding of blanching techniques, it’s helpful to familiarize yourself with related terminology:

- Parboiling: A pre-cooking process that improves blanching efficiency, especially for root vegetables.

- Shock cooling: Rapid cooling after blanching to minimize nutrient loss and preserve the desired texture and color.

By comprehending the principles and practices of blanching, you can effectively preserve the quality and freshness of your food products, ensuring their nutritional value and culinary enjoyment.