Essential Guide To Pneumatic Nailer Pressure Settings For Optimal Performance

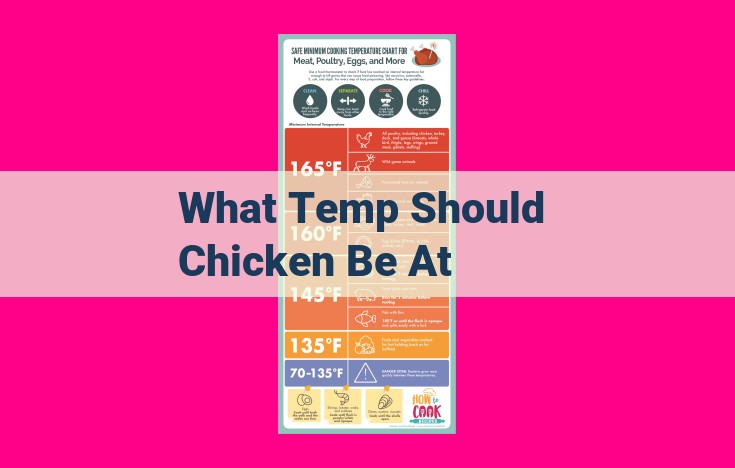

Pneumatic nailers should operate within a specific range of pressure to ensure optimal performance and safety. Typically, low-pressure nailers range from 60 to 120 PSI, medium-pressure nailers from 90 to 150 PSI, and high-pressure nailers from 120 to 180 PSI. Manufacturer-recommended settings should be followed to prevent damage to the nailer, improper nail driving, and potential hazards.

Nailer Pressure: A Key to Nailing Success

Every experienced nailer knows the importance of following manufacturer-recommended nailer pressure settings. It’s not just a matter of convenience; it’s a matter of safety and efficiency. When you use the correct pressure, you’re not only ensuring that your nails are driven in properly, but you’re also reducing the risk of accidents and damage to your tools and materials.

Think of it this way: a nail is like a miniature catapult. The nailer is the spring that launches it, and the pressure setting determines how hard it hits. Too little pressure, and the nail won’t go in all the way. Too much pressure, and you risk bending or breaking the nail, or even damaging the surface you’re nailing into.

That’s why it’s so important to find the sweet spot—the pressure setting that’s just right for the job. This will vary depending on the type of nailer you’re using, the size and type of nails you’re using, and the material you’re nailing into.

Fortunately, most nailer manufacturers provide a recommended pressure range for each of their models. By following these guidelines, you can be sure that you’re getting the most out of your nailer and your nails.

So, don’t be afraid to consult your nailer’s owner’s manual before you start nailing. It’s a small investment of time that can save you a lot of headaches in the long run.

Choosing the Right Nailer: Unlocking the Power of Precision

When tackling your next nailing project, selecting the right tool is paramount. Nailers come in various configurations, each tailored to specific tasks. To ensure optimal performance, it’s crucial to match the nailer to your project’s unique requirements.

Factors to Consider When Choosing a Nailer

1. Project Scope:

Consider the size, complexity, and materials of your project. Heavy-duty framing demands a powerful framing nailer, while delicate finishing touches call for a precise finish nailer.

2. Nail Type:

Different nailers are compatible with specific nail sizes and types. Ensure that the nailer you choose can handle the length, gauge, and head type of nails you need.

3. Power Source:

Nailers come powered by either electricity or compressed air. Electric nailers offer convenience and portability, while air-powered nailers provide greater power and versatility. Choose the power source that best suits your project and work environment.

4. Features:

Consider additional features that enhance efficiency and safety. Adjustable depth settings allow precise nail penetration, while tool-free nail loading saves you time. Safety features, such as trigger locks and anti-dry fire mechanisms, protect you from accidents.

5. Budget:

Nailers range in price depending on their features and quality. Determine your budget and select a nailer that offers the best value for your needs.

By considering these factors, you can ensure that you choose the right nailer for your project. This investment will empower you with the precision and efficiency needed to turn your vision into a reality.

Coil Nailers: The Workhorse for Efficient Nailing

In the world of nailing, coil nailers shine as the epitome of efficiency and versatility. These remarkable tools are designed to effortlessly drive a continuous stream of nails, making them indispensable for projects where speed and precision are paramount.

Coil nailers are characterized by their ability to hold a coil of nails, usually between 100 and 300 nails, which eliminates the need for frequent reloading. This feature not only saves you time but also reduces the risk of interruptions during your project.

The applications of coil nailers are vast, ranging from framing to roofing and siding. They are particularly well-suited for projects that require high-volume nailing, such as:

- Framing walls and roofs

- Installing sheathing and subflooring

- Attaching siding and trim

- Building decks and fences

Coil nailers come in a variety of sizes and strengths to accommodate different projects. Smaller coil nailers are ideal for lighter-weight materials and smaller nails, while larger models are designed for heavier-duty tasks and larger nails. When selecting a coil nailer, consider the size and type of nails you will be using, as well as the scope of your project.

Brad Nailers: The Precision Tools for Small Finishing Projects

In the realm of woodworking, there’s a nail gun for every task. Among these specialized tools, brad nailers stand out as indispensable companions for small finishing projects. These lightweight and compact nailers shoot tiny brad nails that sink seamlessly into wood, leaving behind virtually invisible entry holes.

Brad nailers are your go-to solution for intricate trim work, delicate molding applications, and even cabinetry assembly. Their ability to fire at precise angles and with pinpoint accuracy makes them ideal for tasks where other nail guns might be too bulky or cumbersome.

Applications of Brad Nailers

Brad nailers excel in a wide range of woodworking projects, including:

- Crown molding: With their ability to shoot nails at an angle, brad nailers effortlessly secure delicate crown molding in place.

- Baseboards: Brad nailers ensure a clean, professional finish when attaching baseboards to walls.

- Window and door casings: The precision of brad nailers allows for a tight, flush fit of casings around windows and doors.

- Furniture assembly: Brad nails provide a secure and invisible hold for assembling furniture components.

- Picture framing: Brad nailers are ideal for securely attaching artwork and photographs within frames.

Characteristics of Brad Nails

The nails used in brad nailers typically range from 1/2 inch to 2 inches in length and have a thin “brad” shape. They are available in various gauges, with higher gauge nails being thinner and less visible. The head of a brad nail is typically either flat or slightly rounded.

Choosing the Right Brad Nailer

When selecting a brad nailer, consider the following factors:

- Air pressure: Brad nailers require an air compressor to operate. Choose a compressor with sufficient pressure output for your nailer.

- Capacity: Brad nailers come with different magazine capacities. Consider the size of your projects and choose a nailer with a magazine that can accommodate enough nails.

- Features: Some brad nailers offer additional features such as adjustable depth control, trigger lock, and ergonomic handles. Consider these features based on your specific needs.

Finish Nailers: Your Precision Partners for Flawless Finishing

As you embark on the art of fine woodworking or home improvement projects that demand impeccable detailing, you’ll discover the invaluable role of finish nailers. These specialized tools are meticulously designed to deliver pinpoint accuracy and exceptional holding power for tasks that require a precise and professional touch. Let’s delve into the captivating world of finish nailers and explore their unparalleled capabilities.

Unveiling the Advantages of Finish Nailers

Finish nailers empower you with a host of benefits that elevate your finishing projects to new heights:

-

Invisible Fastening: Their delicate nails are virtually undetectable, leaving your surfaces pristine and blemish-free. This makes them ideal for cabinetry, molding, and decorative woodwork.

-

Superior Holding Power: Despite their diminutive size, finish nails possess remarkable holding strength, ensuring your projects withstand the test of time and use.

-

Ergonomic Comfort: Finish nailers are often designed with lightweight and well-balanced bodies, reducing fatigue during extended use, allowing you to work with ease.

Diverse Applications for Finish Nailers

The versatility of finish nailers knows no bounds. They excel in a myriad of applications, including:

-

Trim and Baseboards: Attaching trim and baseboards with precision, ensuring a seamless and elegant finish.

-

Cabinets and Doors: Securing cabinet doors, drawers, and other intricate components, leaving no trace of their presence.

-

Furniture Making: Creating sturdy and beautiful furniture pieces, where every nail is a testament to your craftsmanship.

-

Decorative Projects: Adding the finishing touches to picture frames, decorative moldings, and other artistic endeavors.

Choosing the Perfect Finish Nailer

Selecting the right finish nailer involves considering several factors:

-

Nail Size: Opt for a nailer that accommodates the nail sizes you commonly use for your projects.

-

Power Source: Choose between pneumatic (air-powered) and electric finish nailers to match your preferred power source.

-

Magazine Capacity: Consider the magazine capacity, as a larger capacity reduces the need for frequent reloading.

-

Features: Look for features such as adjustable depth of drive, tool-free jam clearing, and a comfortable grip to enhance your user experience.

By embracing the power of finish nailers, you unlock a world of precise and professional finishing, transforming your projects into masterpieces that will impress even the most discerning eyes.

Framing nailer: Provide an overview of the power and durability of framing nailers for heavy-duty construction.

Framing Nailers: Power and Durability for Heavy-Duty Construction

Unleashing the Beast

In the realm of construction, framing nailers stand tall as the titans of heavy-duty fastening. These powerful tools are indispensable for framing houses, erecting walls, and tackling any task that demands sheer strength and precision.

Built for Endurance

Framing nailers are engineered to withstand the relentless demands of construction sites. Their robust frames, constructed from high-grade materials such as aluminum or magnesium, can handle the rigors of constant hammering. Their beefy firing mechanisms deliver consistent power, driving nails effortlessly into even the toughest lumber.

Nail-Driving Dominance

Framing nailers are typically powered by compressed air and feature magazines that can hold up to 350 nails. This ample capacity enables uninterrupted operation, minimizing reloading downtime and maximizing productivity. The nails they use, known as framing nails, are specifically designed for heavy-duty applications, with thick shanks and flattened heads for maximum holding power.

Versatility and Control

While framing nailers excel in heavy-duty construction, they also offer versatility for a range of framing tasks. They can handle a wide variety of nail sizes and types, from 2-inch to 3-1/2-inch nails. Additionally, their adjustable depth settings allow for precise nail placement, ensuring a secure and professional finish.

Choosing the Right Nailer

Selecting the optimal framing nailer depends on the specific requirements of the project. Consider the nail capacity, firing rate, and ergonomics of the tool. Also, ensure that the nailer is compatible with the air compressor being used.

Optimizing Performance

To maximize the performance of a framing nailer, adhere to the manufacturer’s recommendations regarding air pressure. Using the correct pressure ensures proper nail driving without damaging the tool or materials. Additionally, regularly lubricating the nailer and cleaning out debris will prolong its lifespan and maintain consistent operation.

Roofing nailer: Explain the specialized features and uses of roofing nailers for securing roofing materials.

The Essential Guide to Roofing Nailers: Securing Your Roof with Precision

When it comes to roofing, the choice of the right nailer can make all the difference in terms of efficiency, safety, and the overall integrity of your roof. Roofing nailers are specialized tools that are specifically designed to handle the unique requirements of securing roofing materials. They provide the power and precision needed to drive nails through multiple layers of shingles, underlayment, and decking.

Features of a Roofing Nailer:

- High-pressure settings: Roofing nailers typically operate at high pressures to ensure that nails are driven securely into the roof’s substrate.

- Specially designed nails: Roofing nailers are compatible with large-headed, corrosion-resistant nails that are optimized for roofing applications.

- Adjustable depth of drive: The nailer’s depth of drive can be adjusted to accommodate different roofing materials and thicknesses.

- Specialized heads: Some roofing nailers feature collated heads that organize nails for quick and efficient loading.

Applications of a Roofing Nailer:

Roofing nailers are essential for a wide range of roofing projects, including:

- Shingle installation: Securing asphalt shingles to the roof deck.

- Underlayment attachment: Installing protective underlayment beneath the shingles.

- Ice and water barrier installation: Attaching moisture-resistant barriers around vulnerable areas of the roof.

Choosing the Right Roofing Nailer:

When selecting a roofing nailer, consider the following factors:

- Roofing material: Different roofing materials have specific nailing requirements.

- Roofing slope: The slope of the roof can affect the nail’s penetration depth.

- Nail length and gauge: Choose nails that provide the appropriate holding power for the roofing material.

Safety Precautions:

When using a roofing nailer, always adhere to safety guidelines:

- Wear protective gear: Use safety glasses, gloves, and ear protection.

- Use the right nails: Incorrect nails can cause damage to the nailer or the roof.

- Maintain the nailer: Keep the nailer clean and well-lubricated.

- Avoid overloading: Do not load more nails than the nailer’s capacity.

By following these guidelines and using the right equipment, you can ensure that your roofing project is completed with precision and safety, protecting your home from the elements for years to come.

Siding Nailers: The Ultimate Tool for Effortless Siding Installation

When it comes to installing siding, precision and efficiency are paramount. Siding nailers offer the perfect solution, seamlessly attaching siding materials with ease. These specialized tools are meticulously designed to deliver optimal performance and flawless results.

Siding nailers boast a range of benefits that make them an indispensable tool for any siding project. Their compact design and lightweight construction provide unmatched maneuverability, allowing you to navigate tight spaces and work with ease. The ergonomic handles ensure comfortable operation, even during extended use.

Applications of Siding Nailers

Siding nailers excel in a wide array of applications. They are ideal for:

- Installing vinyl and fiber cement siding

- Attaching trim, molding, and fascia

- Completing lap joints and corner boards

- Securing soffit and roofing underlayment

The precise nailing action of siding nailers produces clean, countersunk nail heads that blend seamlessly with the siding material. This professional-grade finish enhances the aesthetic appeal of your project.

Compatibility and Versatility

Siding nailers are compatible with a range of nail sizes and types, giving you the flexibility to match the specific requirements of your siding material. They can accommodate galvanized, stainless steel, and aluminum nails to ensure corrosion resistance and durability.

Tips for Using Siding Nailers

To achieve optimal results, consider these tips:

- Choose the right nails: Ensure the nails are compatible with the siding nailer and the siding material.

- Adjust the pressure settings: Different nailers and siding materials require different pressure settings. Consult the manufacturer’s instructions for guidance.

- Wear safety gear: Always wear protective eyewear, gloves, and a dust mask when operating a siding nailer.

Siding nailers are an essential tool for any siding project. Their precision, efficiency, and versatility make them the perfect choice for DIY enthusiasts and professional contractors alike. With the right siding nailer, you can achieve stunning results and elevate the exterior of your home with ease.

Nailing the Perfect Joint: Nail Specifications and Compatibility

In the realm of carpentry, nailing is an essential skill that requires precision and attention to detail. Understanding the specifications of nails and their compatibility with different nailers is crucial for achieving sturdy and aesthetically pleasing results. Let’s delve into the intricacies of nail specifications and explore how they impact nail performance.

Length, Gauge, and Head Type: A Triad of Nail Attributes

The length of a nail determines how deeply it can penetrate into the material being fastened. Nails come in various lengths, measured in inches or millimeters, to accommodate different thicknesses of materials. The gauge, on the other hand, refers to the diameter of the nail shaft. Higher-gauge nails are thinner and suitable for smaller projects, while lower-gauge nails are thicker and ideal for heavy-duty applications.

The head type of a nail refers to its shape and function. Common head types include flat, round, and oval. Flat-head nails are used for general-purpose applications, while round-head nails provide a larger bearing surface for better grip. Oval-head nails, commonly known as countersunk nails, are designed to be driven below the surface of the material, creating a smooth, flush finish.

Nail Compatibility: Striking a Harmony

Nail compatibility is paramount for optimal nailing results. The nail must be compatible with both the nailer and the pressure settings. Using nails that are too long for the nailer can lead to bending or damage to the nailer. Conversely, nails that are too short may not provide sufficient holding power. Similarly, improper pressure settings can result in nails that are either underdriven or driven too deeply, compromising joint strength and stability.

Precision Pressure Control: The Magic Behind the Nail

Pressure control devices play a pivotal role in ensuring that nails are driven with the correct force. These devices regulate the air pressure supplied to the nailer, allowing for precise adjustment of the driving force. Air compressors, which provide the compressed air for nailing, come in various capacities, pressure outputs, and airflow rates. Matching the air compressor to the specific nailer and pressure requirements is essential for achieving consistent and accurate nailing.

Pressure Ranges: A Guide for Nailers

Nailers can be classified into three pressure ranges:

- Low-pressure nailers: Operate at pressures typically below 100 pounds per square inch (psi), making them suitable for small-scale projects and finishing work.

- Medium-pressure nailers: Provide higher driving force with pressures ranging from 100 to 150 psi, ideal for general-purpose nailing tasks.

- High-pressure nailers: Designed for heavy-duty applications, these nailers operate at pressures exceeding 150 psi, delivering maximum power for framing and roofing projects.

Understanding nail specifications and implementing proper pressure control techniques are the cornerstones of successful nailing. By considering the length, gauge, and head type of nails and matching them with the appropriate nailer and pressure settings, you can ensure that your nailing projects are both durable and aesthetically pleasing.

Nail Compatibility: The Key to Nailing Perfection

When it comes to nailing, compatibility is paramount. Matching the right nails to your nailer is crucial for optimal performance and safety. Just as Cinderella’s glass slipper fit her perfectly, the wrong nails will prevent your nailer from performing its best.

Why Compatibility Matters

- Nailer Performance: Nails that are too short, too long, or the wrong gauge can get jammed, damage the nailer’s mechanism, or even cause injury.

- Nail Holding Power: Proper nail compatibility ensures the nails have sufficient holding power to withstand the forces they will encounter.

- Nail Head Appearance: The nail head should be flush with the surface or slightly countersunk for a professional-looking finish.

Nailer Pressure and Compatibility

The pressure settings of your nailer must be compatible with the nails you’re using. Low-pressure nailers require smaller nails, while high-pressure nailers can handle larger nails. If the pressure is too low, the nails may not penetrate the surface deeply enough. Conversely, if the pressure is too high, the nails may be driven too deeply, causing the wood to split.

Nail Length and Gauge

Nail length refers to the distance from the head to the tip, while gauge indicates the thickness of the nail. Longer nails provide greater holding power, while thicker nails are less likely to bend or snap. Choose nails that are long enough to penetrate the workpiece without protruding too far.

Nail Head Type

Nail head types include round, flat, oval, and countersunk. Round heads are commonly used for general construction, while flat heads are less visible. Oval heads provide a decorative touch, and countersunk heads are ideal for finishing work where the nail should be hidden.

By understanding the importance of nail compatibility and choosing the right nails for your nailer, you can ensure nail projects that are both efficient and professional-looking. Remember, the key is to match the nails to the nailer’s pressure settings, length, gauge, and head type. With proper compatibility, you’ll have the confidence to tackle any nailing task with ease.

Mastering the Art of Nailing: A Comprehensive Guide to Pressure Control

In the realm of construction and carpentry, the humble nail holds a pivotal role, binding materials together and giving life to countless structures. However, to achieve flawless nailing results, it’s essential to not only select the right nailer but also master the art of pressure control.

Pressure Control Devices: The Unsung Heroes of Nailing

Pressure control devices serve as the gatekeepers of air pressure in nailing systems. These ingenious mechanisms ensure that the nailer exerts the optimal amount of force on the nail, driving it securely into the workpiece without causing damage or splitting.

Types of Pressure Control Devices

There are two primary types of pressure control devices:

-

Regulators: These devices allow you to adjust the air pressure entering the nailer, giving you greater control over the driving force.

-

Valves: Valves work by modulating the air flow to the nailer, ensuring consistent nailing pressure regardless of the air pressure in the system.

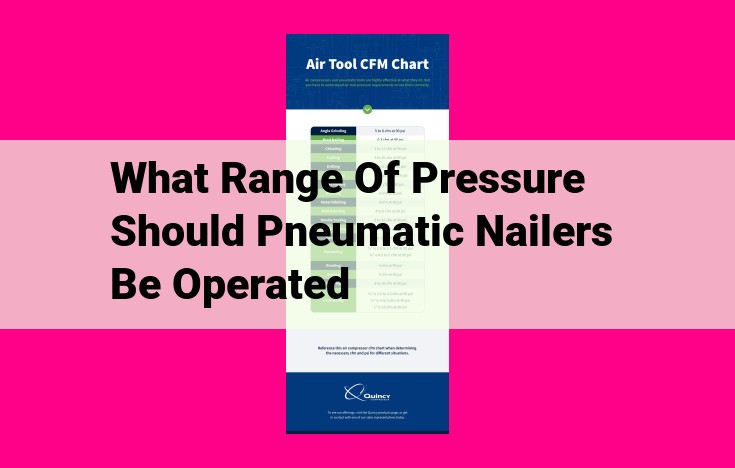

Understanding Air Compressor Capacity

The air compressor, the heart of your nailing system, plays a crucial role in pressure control. Its capacity, measured in cubic feet per minute (CFM), determines how much air it can deliver to the nailer. A compressor with insufficient CFM can’t maintain adequate pressure, resulting in inconsistent nailing results.

Pressure Ranges for Nailers

Nailers are typically designed to operate within specific pressure ranges:

-

Low-pressure nailers: Ideal for delicate tasks or use on thin materials, these nailers typically operate at pressures below 90 PSI.

-

Medium-pressure nailers: The workhorses of the construction industry, these nailers operate at pressures between 90 and 120 PSI, making them suitable for most general-purpose applications.

-

High-pressure nailers: Designed for heavy-duty tasks, these nailers require pressures exceeding 120 PSI to drive nails into dense materials like concrete or hardwoods.

By understanding the function of pressure control devices and mastering the art of selecting the right air compressor and pressure settings, you can transform your nailing endeavors from frustrating to flawless. Remember, the key to successful nailing lies in finding the perfect harmony between the nailer, the nail, and the air pressure. With practice and a keen eye for detail, you’ll become an expert in the art of precision nailing.

Mastering the Art of Nail Gun Mastery: A Comprehensive Guide

Whether you’re a seasoned pro or embarking on your first DIY project, understanding the intricacies of nail guns is essential for achieving flawless results. This comprehensive guide will delve into the crucial factors that influence nail gun performance, empowering you with the knowledge to handle any nailing task with confidence.

Perfecting Nailer Settings

Manufacturer-Recommended Pressure Settings: The Golden Rule

Every nail gun comes with manufacturer-recommended nailer pressure settings. Adhering to these guidelines is paramount. Why? Because using the correct pressure ensures optimal nail penetration, holding power, and prevents damage to the workpiece. Deviating from these settings can lead to subpar results, so it’s always wise to consult the user manual.

Choosing the Right Nailer: Matching Your Needs

The type of nail gun you choose depends on the specific task at hand. From delicate finishing work to heavy-duty framing, there’s a nailer model designed for every job. Consider factors such as the size and type of nails you’ll need, the power requirements, and your overall comfort with the tool.

Exploring the Nailer Landscape

Coil Nailers: Speedy and Efficient for Large Projects

With their continuous coil feed system, coil nailers excel in applications where speed and efficiency are crucial. Ideal for framing, sheathing, and fencing, they offer a high volume of nails without the need for frequent reloads.

Brad Nailers: Precision for Delicate Finishing

For intricate finishing tasks, brad nailers are your go-to choice. These lightweight tools use small, headless nails to create near-invisible fastenings in moldings, trim, and cabinetry.

Finish Nailers: The Ultimate Precision

When demanding the utmost precision in finishing work, finish nailers deliver. They drive 15- to 16-gauge nails with a clean countersink, leaving a virtually seamless finish.

Framing Nailers: Power and Durability for Heavy-Duty Construction

For heavy-duty construction, framing nailers are the workhorse you need. These powerful tools excel in driving large framing nails into thick lumber, ensuring sturdy connections.

Roofing Nailers: Specialized for Secure Roofing

Specifically designed for roofing applications, roofing nailers feature unique features like adjustable shingle guides and high-capacity nail magazines. They provide the precision and efficiency needed for securing roofing materials quickly and securely.

Siding Nailers: Streamlining Siding Installation

For siding installation, siding nailers offer a dedicated solution. These tools drive specialized siding nails with consistent spacing and depth, ensuring a professional-looking finish.

Nail Specifications: Finding the Perfect Match

The length, gauge, and head type of nails you choose have a profound impact on nail performance and compatibility with your nailer. Understanding these specifications will help you achieve the desired results.

Ensuring Nail Compatibility

Matching nails to the specific nailer and pressure settings is crucial. Incompatible nails can cause jamming, damage to the nailer, or subpar fastening. Always consult the tool manual to determine the recommended nails for your model.

Pressure Control: Mastering the Balance

Pressure control devices regulate the force with which nails are driven into the workpiece. Selecting the appropriate pressure setting is essential for optimal nail penetration and holding power.

Air Compressor Essentials

An air compressor provides the air pressure for your nail gun. Consider the capacity, pressure output, and airflow rate of the compressor to ensure it meets the demands of your nailer.

Pressure Ranges for Nailers

Different nailers operate within specific pressure ranges.

- Low-pressure nailers: Ideal for delicate finishing work and brad nailing.

- Medium-pressure nailers: Designed for general-purpose projects, such as trim and molding installation.

- High-pressure nailers: For heavy-duty applications like framing and roofing.

Mastering the art of nail gun operation involves understanding the intricacies of nailer settings, types, nail specifications, compatibility, and pressure control. By following these guidelines, you’ll be equipped to handle any nailing task with precision, efficiency, and confidence. Remember, safety should always be your top priority, so always wear appropriate protective gear and follow all manufacturer instructions. Happy nailing!

Pressure Ranges for Nailers: Matching the Job

When it comes to nailing, pressure matters. Choosing the right pressure setting for your nailer is crucial for optimal performance and safety. Different nailers have different pressure requirements, and mismatched settings can lead to nail damage or even injury. Let’s dive into the world of nailer pressure ranges to help you get the job done right.

Low-Pressure Nailers: Precision and Versatility

Low-pressure nailers operate at a modest pressure range, typically 70-90 PSI. They’re ideal for delicate finish work where precision and minimal damage are essential. These nailers are compatible with smaller nails, such as brad nails and finish nails, making them perfect for cabinetry, molding, and other fine woodworking projects.

Medium-Pressure Nailers: A Workhorse for Small Jobs

Medium-pressure nailers offer a higher pressure range of approximately 90-120 PSI. They’re versatile and suitable for a wider range of applications, including framing, siding, and roofing projects. These nailers can handle slightly larger nails, such as siding nails and roofing nails, and provide a balance between power and precision.

High-Pressure Nailers: Powerhouse for Heavy-Duty Tasks

High-pressure nailers are the heavy hitters of the nailing world, operating at a pressure range of 120 PSI and above. They’re designed for demanding jobs that require maximum power, such as framing and roofing. These nailers can easily drive large nails into tough materials and are indispensable for large-scale construction projects.

Choosing the Right Pressure Setting

Matching the nailer’s pressure setting to the job at hand is paramount. Using too low pressure can result in nails not being driven completely, while excessive pressure can damage nails or even the workpiece. Consult the manufacturer’s instructions for the recommended pressure settings for your specific nailer and nails.

Remember, nailer pressure is just one part of the equation. Nailers also rely on air compressors to supply the necessary air pressure. Choose an air compressor with sufficient capacity, pressure output, and airflow rate to ensure optimal nailer performance. By selecting the right pressure range for your nailer and air compressor, you’ll not only achieve professional-looking results but also enhance safety and efficiency on every project.

Understanding Nailers: A Comprehensive Guide to Nailer Settings, Types, and Compatibility

When embarking on a nailing project, whether it’s a DIY home improvement or a large-scale construction endeavor, selecting the right nailer and understanding its proper operation are crucial for ensuring success. In this comprehensive guide, we’ll delve into the intricacies of nailers, exploring their settings, types, and nail compatibility for optimal results.

Nailer Settings: A Foundation for Success

Before wielding the power of a nailer, it’s paramount to adjust its manufacturer-recommended pressure settings. These guidelines are established for a reason: they ensure that the nailer drives nails precisely and securely. Utilizing pressure settings that are either too low or too high can lead to unsatisfactory results, including nail pop-outs or premature nail failures.

Furthermore, choosing the appropriate nailer model for your specific needs is essential. Consider the nature of your project, the materials you’ll be working with, and the expected nail size. For example, a framing nailer exudes power and durability for heavy-duty construction, while a brad nailer excels in delicate finishing tasks.

Types of Nailers: A Tool for Every Job

The world of nailers is vast and varied, each type designed for a specific purpose. Let’s explore the common types of nailers and their applications:

- Coil nailer: A versatile tool for high-volume fastening, coil nailers are often used in sheathing, framing, and other construction tasks.

- Brad nailer: Ideal for small, delicate finishing projects, brad nailers offer precision and finesse.

- Finish nailer: A craftsman’s choice, finish nailers excel in cabinetry, molding, and other fine woodworking applications.

- Framing nailer: The workhorse of construction, framing nailers drive nails effortlessly into hefty lumber, making them suitable for framing walls, floors, and roofs.

- Roofing nailer: Specifically designed for securing roofing materials, roofing nailers handle roofing shingles with ease and efficiency.

- Siding nailer: Perfect for installing siding panels, siding nailers ensure a secure and weather-resistant hold.

Nail Specifications: The Right Nail for the Job

When selecting nails for your nailer, it’s crucial to consider their length, gauge, and head type. These specifications play a significant role in nail performance and compatibility with different nailers. A properly sized and shaped nail will drive securely into the material without bending, splitting, or causing damage.

Nail Compatibility: A Match Made in Construction

Matching nails to your specific nailer and pressure settings is paramount for optimal results. Using nails that are either too small or too large can compromise nail performance and even damage the nailer. Additionally, ensuring that the nails are compatible with the nail magazine or cassette of your nailer is essential to avoid jams and malfunctions.

Pressure Control: Striking the Right Balance

Pressure control devices play a vital role in regulating the force at which nails are driven. These devices ensure that nails are driven consistently and with the appropriate amount of force. Air compressors, which supply the air pressure to the nailer, come with varying capacities, pressure outputs, and airflow rates. Selecting the right air compressor for your nailer is crucial to maintaining optimal pressure levels and preventing nail jams or compressor overheating.

When it comes to pressure ranges for nailers, they can be categorized as low-pressure nailers, medium-pressure nailers, and high-pressure nailers. Each type is designed for specific applications, with low-pressure nailers suitable for delicate tasks, medium-pressure nailers for general construction, and high-pressure nailers for heavy-duty framing and roofing work.

By understanding nailer settings, types, and compatibility, you’ll be well-equipped to select the right tool for the job and achieve professional-grade nailing results. Remember, the key to nailing success lies in attention to detail and a deep understanding of your tools. So, the next time you pick up a nailer, take a moment to appreciate its intricacies, and you’ll discover a world of seamless nailing possibilities.

Mastering Nail Gun Pressure: A Guide to Medium-Pressure Nailers

It’s no secret that nailing can be a daunting task. But armed with the right knowledge, you can conquer any nailing project with ease. One crucial element that often goes overlooked is nail gun pressure. In this comprehensive guide, we’ll dive into the world of medium-pressure nailers, so you can wield this powerful tool like a seasoned pro.

What are Medium-Pressure Nailers?

Medium-pressure nailers are the workhorses of the nailing world, striking the perfect balance between power and versatility. Designed for a variety of applications, these nailers operate within a pressure range of 60 to 90 psi.

Why Use a Medium-Pressure Nailer?

- Perfect for mid-weight materials: Medium-pressure nailers excel at driving nails into medium-density materials like plywood, framing lumber, and decking.

- Versatile applications: From building decks to framing walls, medium-pressure nailers handle a wide range of projects with precision.

- Cost-effective: Compared to high-pressure nailers, medium-pressure models offer a more economical option while still delivering solid performance.

Tips for Using Medium-Pressure Nailers

- Choose the right nails: Always consult the manufacturer’s recommendations for nail specifications compatible with your nailer.

- Adjust the pressure: Fine-tune the pressure settings for optimal performance based on the material and nail size.

- Maintain your nailer: Regular cleaning, lubrication, and adjustments ensure your nailer remains in top working condition.

Mastering nail gun pressure is essential for a successful nailing experience. By embracing the power and versatility of medium-pressure nailers, you can tackle your projects with confidence. Remember to follow the tips outlined above and always refer to your manufacturer’s instructions for specific guidelines. Happy nailing!

High-Pressure Nailers: The Powerhouses of Heavy-Duty Construction

High-pressure nailers, the unsung heroes of construction, are the mighty tools that make light work of robust tasks. These powerhouses deliver unparalleled force, tackling the most demanding projects with ease.

Unlike their low-pressure counterparts, high-pressure nailers utilize air compressors to generate exceptional pressure, enabling them to drive nails into thick materials with impeccable precision. Their robust design withstands the rigors of heavy-duty construction, making them the go-to choice for professionals seeking efficiency and accuracy.

When selecting a high-pressure nailer, consider the nail gauge and length you need for your project. Heavier materials require thicker gauge nails and longer lengths. It’s crucial to match the nail size to the nailer’s capabilities for optimal performance.

Air compressor compatibility is another critical factor. High-pressure nailers require powerful air compressors with sufficient capacity and pressure output. Inadequate air supply can compromise performance and lead to premature wear on the nailer.

Operating high-pressure nailers requires proper safety measures. Always wear protective gear, including safety glasses and earplugs. Ensure the nailer is properly adjusted and maintained, following the manufacturer’s instructions.

With high-pressure nailers in your arsenal, prepare to conquer even the most challenging construction projects with unmatched efficiency and precision. Their raw power and versatility make them the ideal solution for framing, roofing, and heavy-duty applications.