Optimize Title For Seo:expert Decolorization Solutions: Unlocking Color Removal Techniques And Ensuring Sustainability

To eliminate colors effectively, consider consulting Decolorization Technology Association and other organizations for guidance. Explore decolorization products such as color removers, laser technology, and specialized equipment. Decolorization techniques involve bleaching, dye stripping, and neutralization, each with specific mechanisms. Professionals like color scientists and textile colorists assist in the process. Government regulations ensure environmental compliance. Sustainable practices and waste management considerations are crucial for responsible decolorization in the dyeing and textile industries.

Unveiling the World of Color Decolorization

In the realm of textiles and beyond, the intricate process of color decolorization plays a vital role. This transformative art involves removing or altering the color of dyed materials, opening up a plethora of possibilities. Behind this intricate process lies a dedicated community of organizations, products, techniques, and professionals, each contributing to the advancement and application of color decolorization.

Decolorization Trailblazers: Key Organizations

Spearheading the charge in color decolorization are organizations such as the Decolorization Technology Association, the American Textile Coloration and Finishing Association, and the Society of Dyers and Colourists. These esteemed bodies foster research, establish industry standards, and provide invaluable support to professionals in the field. They serve as hubs of knowledge and innovation, driving progress in color decolorization practices.

-

Decolorization Technology Association (DTA): As the foremost authority on decolorization technology, the DTA promotes cutting-edge research, organizes industry conferences, and facilitates collaboration among professionals. Their dedication to advancing the field is instrumental in shaping the future of color decolorization.

-

American Textile Coloration and Finishing Association (ATFA): With a focus on the textile industry, the ATFA provides a platform for professionals involved in dyeing, printing, and finishing processes. Their expertise encompasses color measurement, textile chemistry, and sustainable practices, making them invaluable resource for the textile community.

-

Society of Dyers and Colourists (SDC): Renowned for its global reach, the SDC serves as a hub for dyers, colorists, and textile professionals from diverse industries. Through conferences, workshops, and publications, they promote the advancement of color science, including the latest advancements in decolorization techniques.

These organizations stand as pillars of support for the color decolorization industry, fostering collaboration, promoting innovation, and ensuring the highest standards of practice.

Additional SEO-optimized keywords:

- Color removal

- Textile decolorization

- Decolorization chemicals

- Color professionals

- Sustainable decolorization

Decolorization Products: Restoring Vibrancy to Faded Fabrics

Color fading is inevitable, but with the right products, you can revitalize your beloved garments. Let’s explore the wonders of decolorization products and their remarkable abilities.

1. Color Removers: The Color-Changing Chameleons

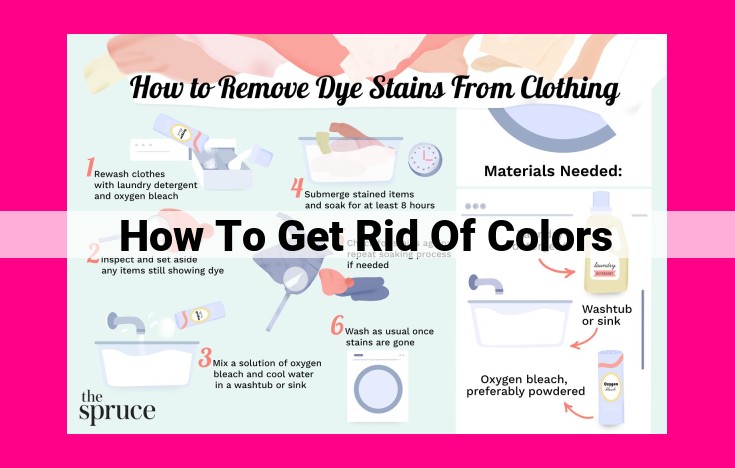

Color removers are like magic wands for fabrics. They work by breaking down the dye molecules, effectively removing or lightening the existing color. They come in various forms, including liquids, powders, and sprays. Simply apply the remover to the stained area, let it dwell for the recommended time, and rinse thoroughly.

2. Decolorizing Agents: The Gentle Color Erasers

Decolorizing agents, such as sodium hydrosulfite, act as milder alternatives to color removers. They selectively target and reduce dye molecules, resulting in a more gradual color removal process. This makes them suitable for delicate fabrics or when you want to remove specific colors without altering the overall tone.

3. Fabric Bleach: The Ultimate Whiteness Booster

Fabric bleach, typically containing sodium hypochlorite (chlorine bleach), is a powerful bleaching agent that can effectively remove stains and restore the original whiteness of fabrics. However, it’s important to use it with caution and always follow the instructions carefully, as it can damage delicate materials.

4. Laser Color Removal: The High-Tech Color Vanisher

Laser color removal utilizes advanced technology to break down dye molecules with intense laser beams. This precise and targeted approach effectively removes unwanted colors without compromising the fabric’s integrity. It’s ideal for removing small stains, logos, or intricate designs that may be difficult to tackle with traditional methods.

Decolorization Techniques: Reclaiming Lost Colors

In the realm of textiles and fabrics, color reigns supreme. However, sometimes, the allure of a vibrant hue can fade, leaving us with unwanted shades or stains. Thankfully, the art of color decolorization offers a lifeline, allowing us to restore our fabrics to their pristine glory. Join us as we delve into the fascinating world of decolorization techniques, unraveling the secrets of color removal and restoring the vibrancy to your wardrobe.

Bleaching: The Classic Color Eraser

Bleaching, a time-honored technique, employs powerful oxidizing agents to strip away color molecules. From household chlorine bleach to industrial-grade hydrogen peroxide, these agents penetrate the fabric, breaking down the color pigments and releasing them into the solution. Bleaching is particularly effective for removing dark or strongly attached colors.

Decolorization: A Precise and Targeted Approach

Unlike bleaching, decolorization involves selectively removing specific colors. This technique utilizes milder chemicals that target certain dye molecules, leaving others undisturbed. Decolorization is often used to correct color mistakes, adjust the shade of a garment, or remove stubborn stains.

Dye Stripping: A Total Color Overhaul

When a complete color transformation is desired, dye stripping offers a comprehensive solution. This technique employs stronger chemicals that dissolve the dye molecules, allowing them to be washed away. Dye stripping is frequently used to remove multiple colors or to prepare fabrics for re-dyeing.

Fading: Subtle Alterations for a Vintage Charm

Fading gently lightens the intensity of colors, giving fabrics a softer, more aged appearance. This technique utilizes mild oxidizing agents or prolonged exposure to sunlight, breaking down color molecules over time. Fading is ideal for creating subtle color effects or achieving a vintage aesthetic.

Neutralization: Restoring Balance and Preventing Damage

After decolorization, neutralization is a crucial step that stabilizes the fabric and prevents further color loss. Neutralizing agents remove residual chemicals and restore the pH balance of the fabric. This step is essential for preserving the integrity of the fabric and preventing damage.

By mastering these decolorization techniques, you can confidently tackle color mishaps, refresh faded garments, and create unique design effects. Remember, always test any decolorization method on an inconspicuous area of the fabric before treating the entire garment. With the power of decolorization, your fabrics will regain their vibrancy, allowing you to express your style with confidence.

Decolorization Equipment: Unraveling the Secrets of Color Removal

In the realm of color removal, specialized equipment plays a pivotal role, enabling efficient and effective decolorization processes. These machines are the workhorses of commercial and industrial applications, harnessing advanced technologies to transform vibrant hues into a blank canvas.

Commercial Decolorization Systems

Key capabilities:

– Large-scale processing: Treat vast quantities of fabrics or other materials simultaneously, catering to high-volume operations.

– Automated operation: Precision-controlled processes minimize manual intervention, ensuring consistent results and reducing labor costs.

– Versatile applications: Handle a wide range of materials, including textiles, plastics, paper, and more.

How it works:

Commercial decolorization systems employ a combination of chemical reagents, heat, and agitation to induce color removal. The reagents react with the dyes, breaking down their molecular structure. Heat accelerates the reaction, while agitation ensures thorough contact between the reagents and the material.

Laser Color Removal Machines

Key capabilities:

– Precise and targeted: Selectively remove specific colors without affecting the surrounding material.

– Non-contact process: No direct contact with the material, minimizing potential damage.

– Intricate patterns: Capable of creating intricate designs and patterns with high precision.

How it works:

Laser color removal machines use a concentrated beam of light to vaporize the dyes. The laser’s wavelength is carefully calibrated to target specific colors, leaving the rest of the material unaffected. The vaporized dyes are then removed using a vacuum system.

Decolorization Chemicals

- List and discuss the key chemicals used in color decolorization, including hydrogen peroxide, sodium hypochlorite (bleach), and sodium dithionite. Explain their chemical properties, safety considerations, and typical applications.

Decolorization Chemicals: The Unsung Heroes of Color Removal

In the world of textile care, decolorization is an essential process that removes unwanted colors from fabrics. And behind every successful decolorization procedure lies a team of unsung heroes: the decolorization chemicals.

Hydrogen peroxide, the bleaching giant, stands tall as one of the most widely used decolorization chemicals. Its oxidizing power penetrates deep into fabrics, breaking down color molecules and leaving behind pristine whites. However, its corrosive nature demands careful handling and proper ventilation.

Sodium hypochlorite, the common bleach, is another effective decolorization agent. Its chlorine molecules attack double bonds in color pigments, causing them to break down and fade. While it’s a powerful bleaching agent, it can also damage delicate fabrics and irritate the skin.

Sodium dithionite, the reducing agent, works in a different way. It reduces the oxidized form of color molecules, converting them into their colorless form. This makes it an ideal choice for removing stubborn stains from delicate textiles.

These chemicals, each with its unique properties and applications, play a crucial role in transforming discolored fabrics into vibrant new creations. But it’s essential to handle them with care, following safety guidelines to minimize risks and protect both fabrics and individuals.

Decolorization Professionals: The Masterminds Behind Color Removal

In the world of decolorization, where the art of removing unwanted colors from fabrics and surfaces is practiced, a dedicated team of professionals plays a crucial role. These experts, each with their unique expertise, come together to ensure the efficient and effective removal of colors, making way for new hues or restoring textiles to their original, pristine state.

Among this group of professionals, color chemists and color scientists stand as the masterminds behind decolorization processes. They possess a deep understanding of the chemistry of dyes and colorants, enabling them to develop and optimize decolorization methods.

Fabric care specialists bring their knowledge of fabrics and their interaction with chemicals to the forefront. They determine the appropriate decolorization techniques for different fabric types, ensuring minimal damage to the material while effectively removing the unwanted colors.

For commercial laundry applications, laundry experts step into the arena. They oversee large-scale decolorization processes, managing the equipment, monitoring chemical concentrations, and ensuring adherence to industry standards.

Lastly, textile colorists, with their expertise in dyeing and color application, contribute their knowledge to the decolorization process. They understand the properties of dyes and pigments, enabling them to select the most suitable decolorization agents and techniques.

These professionals, working in unison, provide a comprehensive approach to decolorization, ensuring the successful removal of unwanted colors from fabrics and surfaces, leaving behind a canvas ready for new creations or a restored appearance.

Government Regulations and Standards: Ensuring Safe and Sustainable Decolorization Practices

In the realm of color decolorization, government agencies play a crucial role in safeguarding the environment and protecting human health. Environmental Protection Agency (EPA), Food and Drug Administration (FDA), and Occupational Safety and Health Administration (OSHA) are among the entities that oversee the regulation and standardization of decolorization practices.

Environmental Concerns

Decolorization processes can pose significant environmental concerns. Dyes and other chemicals used in decolorization can potentially contaminate waterways and damage aquatic ecosystems. The EPA enforces regulations that limit the discharge of these substances into the environment. They establish effluent guidelines and standards for the textile industry, ensuring that wastewater from decolorization processes meets acceptable levels of pollutants.

Safety Considerations

Decolorization chemicals can be hazardous, posing risks to workers and the public. OSHA sets workplace safety standards to minimize exposure to these substances. The agency mandates the use of personal protective equipment, proper ventilation, and safe handling procedures for decolorization chemicals.

Compliance and Enforcement

Government agencies conduct inspections to ensure compliance with regulations. They may impose fines or other penalties for violations. This strict enforcement incentivizes businesses to adopt responsible decolorization practices and protect the environment and human health.

Ongoing Research and Collaboration

Government agencies also play a vital role in promoting research and collaboration in the field of decolorization. They fund studies that explore innovative and sustainable methods to remove color from textiles and other materials. This ongoing research contributes to the development of more environmentally friendly decolorization technologies.

By adhering to government regulations and standards, businesses can minimize the environmental and safety risks associated with decolorization practices. These regulations provide a framework for responsible and sustainable operations, safeguarding the health of workers, the public, and the planet.

Additional Considerations for Color Decolorization

Beyond the technical aspects of decolorization, there are additional considerations that play a crucial role in this field. These include:

-

The Dyeing and Textile Industries: Decolorization has a significant impact on the dyeing and textile industries. Color removal techniques are essential for fabric manufacturers to correct dyeing errors, create new colorways, and ensure the consistency and quality of their products.

-

Waste Management: Decolorization processes generate wastewater and other byproducts that must be managed responsibly to minimize environmental impact. Sustainable practices, such as recycling and the use of eco-friendly chemicals, are becoming increasingly important in this industry.

-

Impact on Water Resources: Decolorization wastewater can contain dyes, chemicals, and other pollutants that can harm aquatic ecosystems if not properly treated. Advanced wastewater treatment methodologies and regulations are crucial for protecting water resources.