Optimized Seo Title:mastering Emt Conduit Cutting: Essential Tools, Techniques, And Safety

To cut EMT conduit effectively, gather essential tools like a conduit cutter and measuring tape. Mark the desired length, insert the conduit into the cutter, and rotate it while applying pressure. For accurate cuts, use a conduit cutter that matches the conduit diameter. Always wear safety glasses and gloves for protection.

Conduit Materials and Tools

- Types of conduit materials: Electrical metal tubing (EMT), galvanized rigid conduit (GRC), liquid-tight flexible conduit (LFNC), non-metallic conduit (PVC, ABS, CPVC).

- Essential tools: Conduit cutter, measuring tape, pencil or marker.

Conduit Materials and Essential Tools: Navigating the Electrical World

When embarking on electrical projects, understanding the appropriate materials and tools for conduit installation is crucial. Conduit, a protective covering that encloses electrical wires, ensures safety and code compliance. Let’s explore the various conduit materials and essential tools you’ll need for successful conduit work.

Types of Conduit Materials

- Electrical Metal Tubing (EMT): This lightweight and bendable metal tubing is ideal for running electrical wires in exposed areas, such as walls and ceilings.

- Galvanized Rigid Conduit (GRC): A sturdy and corrosion-resistant metal conduit used for protecting wires in hazardous environments or where added strength is required.

- Liquid-Tight Flexible Conduit (LFNC): This flexible conduit with a liquid-proof jacket is suitable for protecting wires in areas exposed to water or chemicals.

- Non-Metallic Conduit (PVC, ABS, CPVC): Made from durable plastic, non-metallic conduit is lightweight, easy to work with, and resistant to corrosion and chemicals.

Essential Tools for Conduit Work

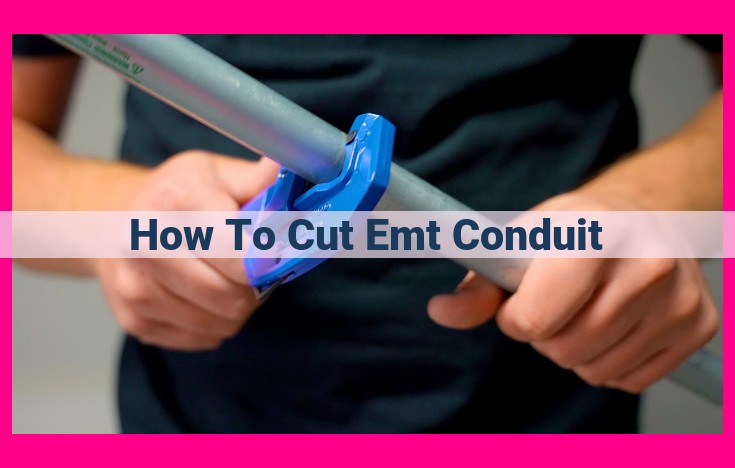

- Conduit Cutter: This specialized tool is used to cleanly cut conduit to the desired length.

- Measuring Tape: An accurate measuring tape is essential for measuring and marking conduit runs.

- Pencil or Marker: For marking and labeling conduit.

Remember, selecting the right conduit material and using the appropriate tools will ensure a safe and compliant electrical installation.

Conduit Installation Tools: Enhancing Precision and Efficiency

When it comes to electrical wiring, conduit plays a crucial role in protecting and organizing wires. Installing conduit requires precision and efficiency, and the right tools can make all the difference. Beyond the essential tools like a conduit cutter, measuring tape, and marking tools, there are several advanced tools that can elevate your conduit installation game.

Hacksaws: Precision Cutting for Clean Conduit Ends

A hacksaw is an essential tool for cutting conduit to precise lengths. Its sharp teeth allow for clean, perpendicular cuts that ensure a secure fit within conduit fittings. When selecting a hacksaw, opt for one with a fine-toothed blade specifically designed for metal cutting.

Rollers: Effortless Conduit Bending Without Kinks

Conduit rollers are used to bend conduit without kinking or deforming it. They consist of a series of hardened steel rollers that guide the conduit as it’s bent, ensuring smooth and consistent curves. Invest in a roller that can handle the diameter and material of the conduit you’ll be using.

Shears: Cutting Conduit at Angles or in Tight Spaces

Shears are ideal for cutting conduit at angles or in tight spaces where a hacksaw is impractical. They feature sharp blades that can easily shear through conduit, even in awkward positions. Choose shears designed for the specific type of conduit you’re working with, such as metal or non-metallic conduit.

Ensuring Safety in Conduit Installation: Essential Precautions

When embarking on conduit installation projects, it’s crucial to prioritize safety to prevent potential hazards. Sharp edges of conduit materials pose a significant risk of cuts and lacerations. Electrical hazards, particularly when dealing with live wires, are another significant concern.

To mitigate these risks, it’s imperative to don appropriate protective gear. Safety glasses safeguard your eyes from flying debris or sparks generated during cutting or bending. Heavy-duty gloves provide a protective barrier against sharp edges and potential electrical shocks.

Remember, safety is not an afterthought but a fundamental aspect of any conduit installation project. By adhering to these precautions, you can minimize the potential for accidents and complete your task safely and efficiently.

Planning and Regulations for Conduit Installation: A Comprehensive Guide

When embarking on electrical conduit projects, meticulous attention to planning and adherence to regulations is paramount. This guide will delve into the crucial aspects of conduit installation, ensuring your electrical system meets safety standards and complies with industry codes.

Conduit Size and Bending Radius

The size of conduit you choose is critical for accommodating the number and size of conductors you’ll be running. Proper sizing prevents overcrowding, which can lead to overheating and electrical hazards. Consult the National Electrical Code (NEC) for specific guidance on conduit sizes.

Bending radii refer to the minimum allowable bend in a conduit. Exceeding these radii can damage conductors or the conduit itself. Follow manufacturer guidelines and use a conduit bender to ensure bends meet specifications.

Grounding and Bonding Requirements

Grounding and bonding are essential safety measures that protect against electrical shock. Grounding provides a path for fault currents to safely dissipate, while bonding connects conductive objects to the grounding system. Proper grounding and bonding help prevent voltage buildup and ensure the safe operation of electrical equipment.

Compliance with the NEC and Local Electrical Codes

The National Electrical Code serves as the minimum standard for electrical installations in the United States. Compliance with the NEC is mandatory to ensure safety and avoid electrical hazards. Additionally, local electrical codes may impose specific requirements that you must adhere to.

Familiarize yourself with the latest editions of the NEC and any applicable local codes. Consulting with a qualified electrician can help ensure your installation meets all necessary requirements. By following these guidelines, you can create a safe and code-compliant electrical conduit system that will serve you well for years to come.

Resources for Conduit Projects

Navigating conduit projects can be a daunting task, especially for beginners. Fortunately, there are plentiful resources available to provide assistance and access to necessary materials.

Professional Assistance

For projects requiring a professional touch, electrical contractors and electricians offer their expertise. Their knowledge and experience ensure safe and efficient conduit installations. Whether it’s complex wiring or troubleshooting issues, these professionals can guide you through the process, providing peace of mind and ensuring code compliance.

Access to Materials

Obtaining high-quality conduit materials is crucial for successful projects. Home improvement stores and online retailers stock a wide range of conduit materials, including EMT, GRC, LFNC, PVC, ABS, and CPVC. These materials vary in size, flexibility, and durability, catering to diverse project requirements.

Whether you’re a seasoned electrician or a DIY enthusiast, having access to the right resources can significantly enhance your conduit project’s outcome. Explore the expertise of professionals and leverage the availability of quality materials to ensure a safe and successful installation.