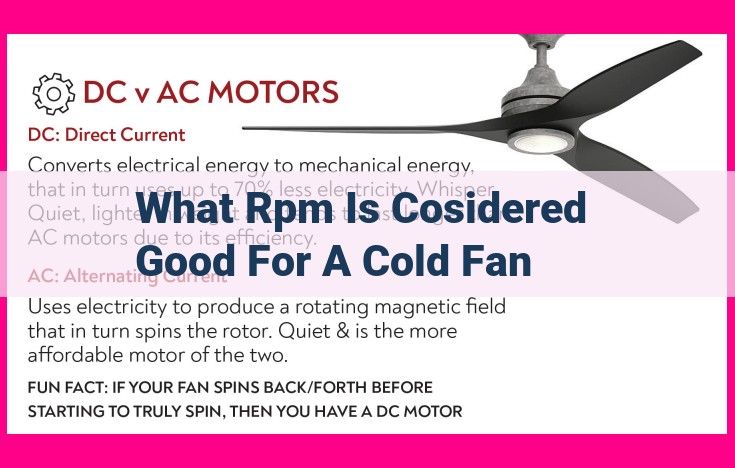

Ideal Cold Fan Rpm: Optimizing Airflow And Noise Levels For Your System

RPM for Cold Fan: Ideal RPM for a cold fan varies with fan size, starting from circa 450 RPM for a 120mm fan, increasing to around 1000 RPM for a 240mm fan. At these speeds, cold fans create low noise levels while providing sufficient airflow to keep components cool during idle or low-load operation.

Fan Size: A Critical Consideration for Optimal Performance

Choosing the right fan size is paramount to ensuring efficient and effective airflow management in your system. Fan size directly affects the airflow rate and static pressure, two key factors that impact your system’s cooling or ventilation capabilities.

Understanding Fan Sizes

Fans come in a range of sizes, from miniature models suitable for small enclosures to large industrial fans capable of cooling entire buildings. The size of a fan is typically measured by its diameter, which is the distance across the fan’s blades.

Selecting the Appropriate Fan Size

The appropriate fan size depends on the specific application and the desired airflow rate. For instance, a small fan may suffice for cooling a personal computer, while a larger fan is necessary for ventilating a large industrial space.

Consider the following factors when selecting a fan size:

- Airflow Rate Requirement: Determine the amount of airflow needed for your application.

- Static Pressure Requirement: Calculate the static pressure needed to overcome resistance in the system.

- Mounting Constraints: Ensure the fan will fit the available space for installation.

Guidance for Specific Applications

- Personal Computers: Fans ranging from 80mm to 120mm are common for cooling PC components.

- Industrial Ventilation: Fans with diameters of 18 inches or larger are typically used for industrial ventilation systems.

- HVAC systems: Fans with diameters ranging from 24 inches to 48 inches are common in HVAC applications.

Remember, selecting the appropriate fan size is essential for optimal system performance. By carefully considering the factors mentioned above, you can choose a fan that meets your specific requirements and ensures efficient airflow management.

Fan Type: Choosing the Right Fit for Your Needs

When it comes to fans, understanding the different types available is crucial for selecting the most efficient and suitable option for your application. From axial to centrifugal and tangential fans, each type possesses distinct characteristics that cater to specific needs.

Axial Fans:

Axial fans, also known as propeller fans, operate on a simple principle: they draw air in and push it out in a parallel direction to the fan’s axis. Their compact design and high airflow capacity make them ideal for applications where space is limited, such as in computers and air conditioners.

Centrifugal Fans:

Centrifugal fans feature a curved blade design that rotates to create a centrifugal force. This force draws air axially into the fan and then discharges it perpendicularly to the intake direction. Centrifugal fans are well-suited for applications requiring high pressure and low noise levels, such as in industrial ventilation and air filtration systems.

Tangential Fans:

Tangential fans utilize a unique scroll-shaped housing that directs the airflow in a tangential direction to the fan’s axis. This design creates a circulating airflow pattern, making tangential fans ideal for applications where even distribution of air is critical, such as in ovens and paint booths.

In summary, axial fans offer high airflow in confined spaces, centrifugal fans excel in high-pressure applications, and tangential fans provide even air distribution. By understanding these types, you can make an informed choice for your specific fan requirements.

Understanding Airflow Rate: The Key to Optimizing Fan Performance

In the world of fans, airflow rate reigns supreme as a crucial factor determining how effectively they cool, ventilate, or exhaust air. Airflow rate measures the volume of air a fan can move in a given amount of time, typically expressed in cubic feet per minute (CFM). It’s not just about blowing a breeze; the right airflow rate is essential for achieving optimal fan performance and comfort in various applications.

Why Airflow Rate Matters

Airflow rate directly impacts a fan’s ability to circulate air effectively. A fan with a higher airflow rate can move more air, resulting in better cooling or ventilation. For example, in a home or office space, a higher airflow rate helps distribute cool air evenly, ensuring a comfortable temperature throughout the room.

Measuring Airflow Rate

Determining the airflow rate of a fan is crucial for selecting the right model for your needs. It can be measured using an anemometer, a device that measures air velocity. By placing the anemometer in the airflow path, you can obtain an accurate reading of the CFM.

Optimizing Airflow Rate

Once you understand the importance of airflow rate, you can take steps to optimize it:

- Selecting the Right Fan Size: The size of the fan should be proportional to the area it needs to cool or ventilate. A larger fan will typically have a higher airflow rate.

- Proper Fan Placement: Position the fan strategically to maximize airflow. Avoid placing it near obstacles or in corners, which can restrict air movement.

- Maintaining Fan Blades: Dirty or damaged fan blades can impede airflow. Regularly clean them to ensure optimal performance.

- Adjustable Speed Settings: Fans with adjustable speed settings allow you to customize the airflow rate to meet specific needs.

By understanding and optimizing airflow rate, you can ensure your fans perform optimally, benefiting from improved cooling, ventilation, or exhaust. Remember, the right airflow rate is the key to a comfortable and efficient indoor environment.

Unveiling Static Pressure: The Silent Force Behind Fan Performance

Every fan, like a symphony conductor, depends on a hidden force to orchestrate its airflow: static pressure. This pressure, measured in Pascals (Pa), represents the resistance that a fan encounters as it pushes air through its passageways.

Impact on Fan Operation

Static pressure exerts a profound impact on fan operation. A fan with insufficient static pressure will struggle to overcome resistance, leading to reduced airflow and inefficient cooling. Conversely, excessive static pressure can overload the fan, causing noise, vibration, and premature failure.

Calculating Static Pressure Requirements

To determine the static pressure required for your specific application, consider:

- The length and diameter of ductwork

- The number of bends and transitions in the system

- The desired airflow rate

Online tools and manufacturers’ specifications can provide guidance on calculating static pressure requirements.

Meeting Static Pressure Requirements

There are several strategies to meet static pressure requirements:

- Fan Selection: Choose a fan with a static pressure rating that exceeds the system requirements.

- Fan Speed Control: Adjust the fan speed to optimize airflow while meeting static pressure needs.

- Duct Modifications: Reduce system resistance by minimizing duct length, bends, and transitions.

- Filter Maintenance: Regularly clean or replace filters to prevent blockage that increases static pressure.

Understanding and managing static pressure is essential for ensuring optimal fan performance and maintaining a comfortable and efficient indoor environment. By carefully considering these factors, you can ensure that your fans play their part effortlessly and harmoniously.

Unveiling the Nuances of Fan Blades

In the realm of air movement, fan blades play a pivotal role in shaping the performance and efficiency of fans. Just as the artist’s brushstrokes give life to a masterpiece, the design and material of fan blades determine the symphony of airflow.

Plastic Blades:

These blades are lightweight and cost-effective, making them a popular choice for budget-conscious applications. Their flexibility allows them to withstand some bending without breaking, but they may be more susceptible to wear and tear over time.

Metal Blades:

Known for their durability and strength, metal blades can withstand high temperatures and harsh environments. Steel blades offer exceptional longevity, while aluminum blades are lighter and more corrosion-resistant. However, metal blades tend to be noisier and more expensive than plastic ones.

Composite Blades:

Combining the best of both worlds, composite blades are typically made from fiberglass or carbon fiber. They offer high strength and low weight, as well as resistance to corrosion and chemicals. Their aerodynamic profiles can enhance airflow efficiency.

Choosing the Right Blades:

The optimal blade material depends on the specific application. For applications where cost and flexibility are paramount, plastic blades may suffice. Where durability and strength are essential, metal blades are a wise choice. Composite blades offer an ideal balance between these qualities, making them suitable for demanding applications.

A Comprehensive Guide to Blade Pitch: Unlocking Fan Efficiency and Minimizing Noise

Have you ever wondered why some fans are more efficient and quieter than others? One of the key factors that contribute to these differences is the blade pitch. Understanding blade pitch and its impact on fan performance can help you make informed decisions when selecting and optimizing fans for your specific applications.

What is Blade Pitch?

Blade pitch refers to the angle at which fan blades are set relative to the **axis of rotation. It is typically measured in degrees and influences two critical aspects of fan performance: efficiency and noise levels.

Influence on Efficiency

A steeper blade pitch results in a higher _airflow rate at higher pressures. This makes fans with steep blade pitches more efficient at moving air against resistance. Such fans are ideal for applications that require high airflow in environments with obstacles or restrictive airflow paths.

Conversely, a shallower blade pitch promotes lower airflow but at _lower pressures. These fans are less efficient but quieter as the blades generate less turbulence and noise at lower speeds. They are suitable for applications that prioritize quiet operation over high air movement.

Impact on Noise Levels

Blade pitch also significantly affects noise levels. Fans with steeper blade pitches tend to be louder, as they generate more turbulence and produce a higher-pitched sound. On the other hand, fans with shallower blade pitches operate more quietly due to reduced turbulence and a lower frequency of sound.

Selecting the Optimal Blade Pitch

Choosing the optimal blade pitch depends on the specific application and requirements. For applications where high airflow and efficiency are paramount, a steeper blade pitch is recommended. In situations where noise levels are a concern, a shallower blade pitch is preferable.

By carefully considering blade pitch and its impact on fan performance, you can select and optimize fans to meet your specific needs. Whether you require maximum airflow, reduced noise levels, or a balance of both, understanding blade pitch empowers you to make informed decisions and achieve optimal fan performance.