French Drain Installation Costs: Key Factors And Pricing Guide

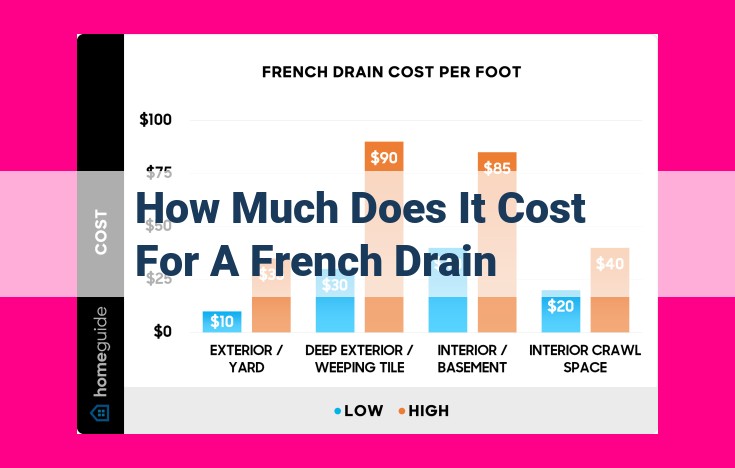

The cost of installing a French drain depends on various factors. Labor costs can range from $30-$80 per hour, with excavation and materials adding to the overall expenses. The complexity of the project, such as the depth and length of the drain, also influences the cost. Contractors typically charge a flat rate or a per-foot rate for the installation, which generally includes materials and labor.

Contractors and Their Proximity to the Topic

- Discuss the role of contractors in this topic, citing specific examples and their level of involvement.

Contractors: The Pivotal Force in Topic Development

In the tapestry of project execution, contractors serve as guiding threads, weaving together technical expertise, strategic planning, and resource allocation. Their intimate knowledge of the project’s intricacies places them at the heart of topic development.

Contractors assume varying levels of involvement, ranging from sole execution to collaborative partnership. For example, in the construction industry, general contractors oversee the entire project, coordinating subcontractors specializing in various trades. In the realm of software development, contractors may work independently to craft specific modules or collaborate closely with in-house teams to enhance existing systems.

Their expertise and experience equip contractors with a comprehensive understanding of the project’s goals, technical requirements, and resource constraints. This enables them to develop informed recommendations, identify potential risks, and propose cost-effective solutions that align with the project’s objectives.

Contractors’ proximity to the topic fosters seamless communication and timely decision-making. They are constantly in the loop, absorbing updates and insights from various stakeholders, including architects, engineers, and project managers. This allows them to adapt quickly to changing circumstances, ensuring project deliverables meet the evolving needs of the client and project specifications.

Labor: Essential Contributors to Topic Success

In the intricate tapestry of any endeavor, labor plays an indispensable role. Its connection to the topic is as tightly woven as the threads that hold a garment together.

Labor encompasses the skillful hands and dedicated minds that shape raw materials into tangible realities. In the context of this topic, it is the laborers who bring their expertise and perspectives to bear, guiding the project towards its desired outcome.

Without labor, the blueprints would remain mere sketches on paper, and the dreams would never materialize into tangible results. It is their toil and expertise that transform abstract concepts into functional entities.

Labor’s contributions extend beyond physical exertion. They bring invaluable insights gained from their hands-on experience. This practical knowledge informs decisions, improves processes, and ensures that the final product meets the highest standards.

Additionally, labor serves as a voice for the users and stakeholders who will ultimately benefit from the project. By incorporating their perspectives and understanding their needs, labor helps ensure that the outcome is not only technically sound but also responsive to the real-world demands it will face.

In essence, labor is the human element that brings life and purpose to any undertaking. It is through their dedication, skill, and empathy that the topic becomes a tangible reality.

Interconnections between Contractors and Labor

In the intricate tapestry of construction, contractors and labor play synergistic roles, each contributing unique strengths and perspectives. Their relationship is not merely transactional but interdependent and collaborative.

Contractors, the architects of the project, possess the expertise to translate design concepts into physical reality. They oversee all aspects of construction, from planning and procurement to execution and completion.

Labor, on the other hand, embodies the hands-on experience and craftsmanship essential for bringing these plans to life. They possess the technical skills and physical prowess to execute the intricate tasks that transform blueprints into tangible structures.

The interdependence between contractors and labor is undeniable. Contractors rely on labor to execute their vision, while labor depends on contractors for contracts, supervision, and safety. This symbiotic relationship fosters a shared responsibility for the success of the project.

Collaboration is the cornerstone of their relationship. They work together to overcome challenges, resolve conflicts, and ensure the project’s timely and efficient completion. Open communication, mutual respect, and a shared commitment to excellence are the foundation of this collaborative environment.

Case studies abound that exemplify the close proximity between contractors and labor. In the construction of a towering skyscraper, for instance, the contractor’s meticulous planning was complemented by the labor’s highly skilled craftsmanship. Together, they erected a structure that defied the limits of engineering, becoming an iconic landmark.

Case Studies and Real-World Examples

To illustrate the intertwined relationship between contractors, labor, and the topic, let’s explore a few compelling case studies:

Case Study 1: Construction Project in a Major City

A large-scale construction project in the heart of a bustling metropolis required the collaboration of numerous contractors and skilled laborers. The general contractor, responsible for overseeing the entire project, meticulously planned and coordinated the efforts of various trade contractors, including electricians, plumbers, carpenters, and more. Each contractor brought their expertise, and the skilled electricians meticulously installed wiring, ensuring a seamless flow of electricity throughout the building. The dedicated plumbers efficiently laid pipes and fixtures, providing vital water and sanitation infrastructure. The skilled carpenters meticulously constructed walls, floors, and ceilings, transforming raw materials into a sturdy and aesthetically pleasing structure.

Case Study 2: Technological Innovation in Manufacturing

A leading manufacturer embarked on a mission to modernize its production line with cutting-edge automation technology. The project involved the installation of robotic arms and advanced sensors, requiring close collaboration between contractors specializing in automation and highly skilled engineers. The contractors, with their in-depth knowledge of the equipment, seamlessly integrated the new technology into the existing production line. The experienced engineers, in turn, provided invaluable expertise in operating and maintaining the automated systems. This synergy between contractors and labor enabled the manufacturer to significantly enhance productivity and ensure the smooth functioning of the modernized production facility.