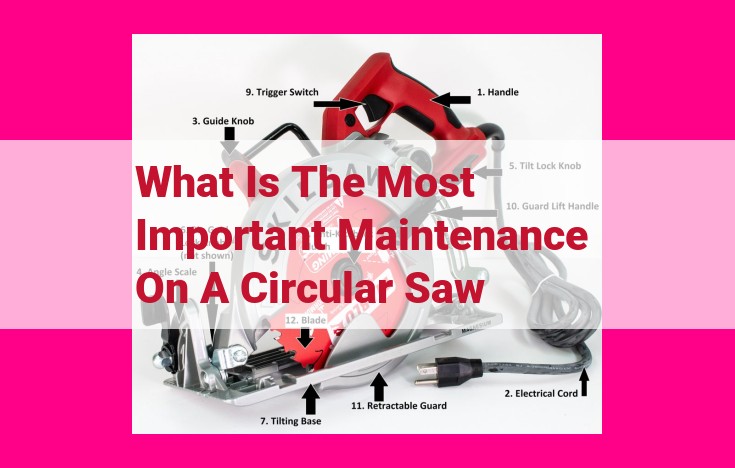

Essential Circular Saw Maintenance: Sharpen, Clean, And Secure For Optimal Performance

Essential maintenance for a circular saw includes regularly sharpening the blade for optimal cutting performance. Additionally, keeping it clean by removing sawdust and debris prevents overheating and ensures smooth operation. Finally, ensure the proper tightness of the blade mounting bolts to prevent the blade from wobbling or becoming loose.

Table Saws: A Comprehensive Guide for Beginners

In the realm of woodworking, the table saw reigns supreme as an indispensable tool. Imagine yourself as a master craftsman, gliding effortlessly through a variety of materials with precision and finesse. It is a gateway to endless creative possibilities, providing the means to shape, cut, and transform your ideas into tangible masterpieces.

A table saw, in essence, is a power tool designed to make precise cuts in wood. At its core lies a rotating blade, concealed within a housing for safety, mounted on a sturdy table that provides stability and support. The table is typically equipped with a fence, a guide that ensures straight and accurate cuts, and a miter gauge for angled cuts.

But beneath this seemingly simple exterior lies a symphony of intricate components, each playing a vital role in the performance and safety of the machine. Understanding these components is not only essential for operating the saw effectively but also for ensuring your own safety.

Primary Components of a Table Saw

-

Blade: The heart of the table saw, the blade is responsible for cutting the material. Its size, shape, and number of teeth determine the type of cuts it can make.

-

Arbor: The arbor is the shaft that holds and rotates the blade. It is typically made of steel and has a flange that secures the blade in place.

-

Motor: The motor provides the power to rotate the blade. It is usually mounted on the underside of the table and connected to the arbor via a belt or chain drive.

-

Housing: The housing encloses the blade and arbor, providing protection from flying wood chips and debris.

-

Cord: The cord provides electricity to the motor. It is important to use a heavy-duty cord that is rated for the amperage of the saw.

-

Blade Guard: The blade guard is a safety device that covers the blade when it is not in use. It is designed to prevent accidental contact with the blade.

-

Riving Knife: The riving knife is a safety device that helps prevent kickback. It is a thin, blade-like piece of metal that extends past the blade and retracts behind it.

-

Anti-Kickback Pawls: Anti-kickback pawls are spring-loaded fingers that help prevent the workpiece from being thrown back at the user. They engage the workpiece as it passes the blade and hold it in place.

-

Trigger Switch: The trigger switch controls the power to the saw. It is typically located on the handle of the saw and must be held down to operate the saw.

By understanding the primary components of a table saw, you can operate it safely and effectively, transforming your woodworking journey into a rewarding and fulfilling experience.

The Essential Components of a Table Saw: A Comprehensive Guide

Delving into the world of woodworking, a table saw stands as a cornerstone tool that empowers craftsmen with precise cuts and intricate designs. Before embarking on your woodworking journey, it’s imperative to familiarize yourself with the table saw’s primary components and their vital roles.

Blade: The Cutting Edge

The beating heart of the table saw is its blade, a rotating, toothed disc responsible for slicing through wood with precision. Blades come in various sizes and configurations, each designed for specific tasks. For instance, finer blades offer smoother cuts, while blades with larger teeth tackle thicker materials.

Arbor: The Blade’s Foundation

The arbor is a cylindrical shaft that securely holds the blade in place. It is connected to the motor and serves as the axis of rotation for the blade. The arbor must be aligned correctly to ensure smooth and accurate cuts.

Motor: The Powerhouse

The motor is the driving force behind the table saw’s operation. It generates the power that spins the arbor and, consequently, the blade. Motors vary in horsepower, which determines the machine’s cutting capacity and overall performance.

Housing: The Protective Encasement

The housing is the protective casing that encloses the motor and other internal components. It shields the user from potential hazards and directs sawdust away from the work area.

Cord: The Energy Conduit

The cord is a flexible electrical cable that supplies electricity to the table saw’s motor. It should be of adequate length and gauge to handle the power requirements of the machine.

Other Essential Components

Beyond these core components, several other features enhance the table saw’s functionality and safety.

- Blade Guard: Protects the user from contact with the spinning blade.

- Riving Knife: Helps prevent kickback by creating a barrier behind the blade.

- Anti-Kickback Pawls: Spring-loaded devices that grip the workpiece, reducing the risk of kickback.

- Trigger Switch: Controls the activation and deactivation of the table saw, ensuring operator control.

Secondary Components of a Table Saw

Beyond the primary components, table saws also feature various secondary elements that provide support and enhanced functionality for a more efficient and safe woodworking experience.

Arbor Bearings: These integral bearings support the arbor, the shaft that holds the blade. They ensure smooth rotation and reduce friction, minimizing blade wobble and enhancing cutting precision.

Gears: Table saws often utilize gears to transmit power from the motor to the arbor. These components enable speed adjustments and allow for a range of cutting applications, from delicate tasks to heavy-duty operations.

Motor Bearings: Critical to the operation of any table saw, motor bearings support the rotating shaft within the motor. They reduce friction and minimize vibration, ensuring the motor functions optimally and extends its lifespan.

Regular Maintenance of a Table Saw: Ensuring Safety, Performance, and Longevity

Maintaining a table saw is crucial for its efficient operation and your safety. Here are some essential tasks to keep your saw in tip-top shape:

Sharpening (Blade)

A sharp blade is a safe blade. Dull blades are more likely to grab and kickback, causing accidents. Sharpen your blade regularly using a blade sharpener or take it to a professional for grinding.

Cleaning

Debris build-up can hinder a table saw’s performance and compromise safety. Regularly clean your saw, paying special attention to the blade guard, riving knife, and anti-kickback pawls. Use a dry cloth or compressed air to remove sawdust and debris.

Tensioning (Belt or Chain)

A properly tensioned belt or chain ensures optimal power transmission and blade speed. Check the belt or chain for any slack or stretch and adjust accordingly using the tensioning knob or adjustment screw.