Choosing Corrosion-Resistant Screws For Cedar Decks: A Guide To Optimal Longevity

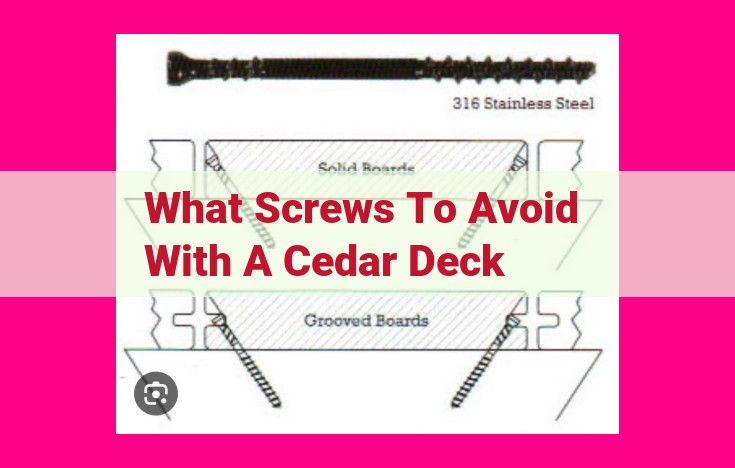

When choosing screws for a cedar deck, avoid general-purpose or galvanized ones as they can react with the natural acids in cedar and cause unsightly stains or corrosion. Stainless steel screws, especially Grade 316 for coastal areas, provide excellent corrosion resistance and longevity in outdoor applications. Stainless steel 410 offers a more budget-friendly option with moderate corrosion resistance.

Corrosion-Resistant Materials: Essential for Outdoor Durability

When it comes to outdoor furniture, fixtures, or any other elements exposed to the relentless forces of nature, corrosion resistance becomes paramount. Corrosion, the dreaded process of metal degradation, can not only compromise the aesthetic appeal of your outdoor spaces but also pose significant safety hazards. Fortunately, there’s a wide range of corrosion-resistant materials available to safeguard your investments and ensure their longevity.

Stainless Steel: A Cut Above the Rest

Among the arsenal of corrosion-resistant materials, stainless steel stands as a shining beacon. Its remarkable ability to withstand rust and corrosion stems from its unique composition, featuring a high chromium content. This protective layer of chromium oxide forms a barrier against the elements, preventing the underlying metal from oxidizing and deteriorating. Moreover, stainless steel’s low maintenance requirements and striking aesthetic add to its allure, making it an ideal choice for outdoor furniture, railings, and architectural elements.

Stainless Steel 316: The Marine-Grade Champion

For applications in marine or coastal environments where the corrosive effects of salt water are amplified, Stainless Steel 316 takes center stage. This grade of stainless steel boasts an enhanced composition, with a higher percentage of chromium and the addition of molybdenum. These reinforcements grant Stainless Steel 316 exceptional resistance to pitting, crevice corrosion, and the harsh effects of chloride ions, making it the preferred choice for boat hardware, coastal structures, and outdoor furniture in seaside settings.

Other Corrosion-Fighting Allies

Beyond stainless steel, there are additional corrosion-resistant materials that deserve consideration:

-

Electrostatic Powder Coating: This advanced technique involves spraying fine powder particles onto metal surfaces, which are then electrostatically charged to bond with the metal. The resulting coating provides a highly durable, chip-resistant, and scratch-resistant finish, extending the life of outdoor furniture and fixtures.

-

Hot-Dipped Galvanizing: This time-tested process involves immersing metal objects in molten zinc. The resulting zinc coating acts as a sacrificial anode, corroding instead of the underlying metal and effectively shielding it from rust and corrosion. Hot-dipped galvanizing is commonly employed for fencing, steel structures, and other outdoor applications.

By embracing these corrosion-resistant materials, you’ll not only enhance the longevity of your outdoor spaces but also minimize maintenance hassles and ensure a pristine appearance for years to come. Invest in corrosion resistance today and enjoy the peace of mind of durable, beautiful outdoor elements that withstand the test of time.

Stainless Steel: The Epitome of Corrosion Resistance for Outdoor Applications

When it comes to outdoor furniture and other applications that face the relentless assault of the elements, corrosion-resistant materials reign supreme. Among these materials, stainless steel stands out as a beacon of durability and aesthetic appeal, offering an unrivaled level of protection against the ravages of rust and decay.

Stainless steel’s exceptional corrosion resistance stems from its alloy composition, which includes chromium. This alloying element forms a thin, invisible layer of chromium oxide on the surface of the steel, acting as a protective barrier against oxygen and moisture. This oxide layer effectively shields the underlying steel from oxidation, preventing the formation of rust.

Furthermore, stainless steel’s low maintenance requirements make it a practical choice for outdoor use. Unlike traditional steel or iron, stainless steel does not require regular painting or sealing to maintain its integrity. Simply cleaning it with mild detergents and water will suffice to keep it looking pristine.

Not only is stainless steel highly resistant to corrosion and easy to maintain, but it also possesses an attractive aesthetic that complements any outdoor setting. Its sleek, silvery finish adds a touch of sophistication to any space, making it an ideal material for furniture, railings, and architectural elements.

Stainless Steel 316: The Ultimate Corrosion-Resistant Champion for Marine Environments

When it comes to outdoor furniture, marine equipment, and other applications exposed to the relentless onslaught of saltwater and harsh elements, corrosion resistance is paramount. Enter Stainless Steel 316, a material that stands head and shoulders above the rest in this battle against rust and decay.

Unveiling the Secrets of Stainless Steel 316

Stainless Steel 316, also known as marine-grade stainless steel, is an alloy composed primarily of iron, chromium, nickel, and molybdenum. This unique blend verleiht it exceptional corrosion-resistant properties, making it the go-to choice for applications where exposure to salt water or other corrosive substances is a constant threat.

Superiority in Marine and Coastal Environments

In the unforgiving marine environment, where saltwater’s corrosive grip can wreak havoc on ordinary materials, Stainless Steel 316 shines as a shining beacon of protection. Its high chromium content forms a protective oxide layer that effectively shields the metal from rust and corrosion, even in the presence of chlorides and other aggressive agents.

Protecting Your Investments from the Elements

Whether it’s your cherished outdoor furniture, essential marine equipment, or intricate architectural details, Stainless Steel 316 provides unparalleled protection for your valuable investments. Its low maintenance requirements and durable nature ensure that you can enjoy the beauty and functionality of your possessions for years to come, without the worries of corrosion eating away at them.

Stainless Steel 410: Budget-Friendly Corrosion Resistance for Your Outdoor Needs

Stainless steel is renowned for its excellent corrosion resistance, making it an ideal choice for applications exposed to the elements. However, not all stainless steels are created equal. Stainless steel 410, a cost-effective option, offers moderate corrosion resistance, making it a suitable choice for certain outdoor applications.

Properties and Applications of Stainless Steel 410

Stainless steel 410 is a martensitic stainless steel, meaning it has a high carbon content. This gives it greater hardness and strength than other types of stainless steel. However, it also makes it less resistant to corrosion, especially in marine environments.

Nevertheless, stainless steel 410 is still a viable option for applications where moderate corrosion resistance is required. It is often used in:

- Automotive parts: Due to its strength and durability.

- Cutlery and flatware: As it is resistant to wear and tear.

- Architectural details: Such as railings and door handles, where aesthetics and moderate corrosion resistance are important.

Cost-Effectiveness

One of the key advantages of stainless steel 410 is its cost-effectiveness. It is a relatively low-alloy steel, which means it contains fewer expensive elements than other types of stainless steel. This makes it a more affordable option for applications where budget is a concern.

While stainless steel 410 may not be as corrosion-resistant as higher alloyed grades like 316, it still offers a cost-effective solution for applications requiring moderate corrosion resistance. Its strength and durability make it a suitable choice for outdoor applications, automotive parts, and cutlery, among others.

Other Corrosion-Resistant Options: Beyond Stainless Steel

When it comes to combating the relentless forces of corrosion in outdoor settings, stainless steel rightfully earns its place as a champion. However, other materials also stand tall against the corrosive assault, offering their own unique set of advantages.

Electrostatic Powder Coating: This cutting-edge technique involves spraying a fine powder onto metal surfaces, which is then electrostatically charged and cured under heat. The resulting coating boasts exceptional durability, resisting chipping, scratching, and the harsh effects of UV exposure. Additionally, electrostatic powder coating presents a plethora of color options, allowing for endless customization to match any design aesthetic.

Hot-Dipped Galvanizing: This ancient yet effective method involves submerging metal objects in molten zinc. The zinc coating that forms upon cooling sacrificially protects the underlying metal, acting as a barrier against corrosion. Hot-dipped galvanizing is particularly suited for industrial applications where heavy-duty protection is paramount.

Electrostatic Powder Coating: The Ultimate Guide to Durable and Aesthetic Protection

When it comes to protecting your metal surfaces from the relentless onslaught of the elements, electrostatic powder coating emerges as a formidable ally. This advanced technique offers an unparalleled combination of durability, aesthetic appeal, and resistance to chipping and scratching.

The process of electrostatic powder coating involves applying a finely ground powder to a metal surface. This powder carries an electrical charge that attracts it to the oppositely charged surface, ensuring a uniform and complete coating. Once applied, the powder is baked at high temperatures, fusing it to the metal and creating a hard, protective layer.

Unlike liquid paints, powder coatings contain no solvents, making them an environmentally friendly choice. Additionally, the wide range of colors available allows for customization to suit any design aesthetic.

Benefits of Electrostatic Powder Coating:

- Exceptional Durability: Powder coatings are highly resistant to abrasion, impact, and weathering, providing long-lasting protection from harsh conditions.

- Wide Color Options: With an extensive palette of colors to choose from, powder coating provides endless possibilities for customization and personalization.

- Resistance to Chipping and Scratching: The hard, fused surface of powder coatings resists chipping, scratching, and deformation, ensuring a pristine appearance.

- Environmental Friendliness: Powder coatings emit no volatile organic compounds (VOCs) during application, making them a sustainable choice for protecting your surfaces.

Hot-Dipped Galvanizing

- Describe the hot-dipped galvanizing process and discuss its effectiveness in preventing rust and corrosion on metal surfaces.

Hot-Dipped Galvanizing: The Steel’s Knight in Shining Armor

Step into the realm of metal protection, where hot-dipped galvanizing reigns supreme as the guardian of your outdoor treasures. This time-honored technique has been used for centuries to shield metal surfaces from the relentless onslaught of rust and corrosion.

Imagine dipping your precious furniture, fences, or outdoor structures into a molten bath of pure zinc. As the metal submerges, it undergoes a transformation. A metallurgical dance ensues, creating an unbreakable bond between the zinc and the steel’s surface. This newly formed layer acts as a galvanized armor, a valiant protector against the harsh elements.

The zinc coating, like a devoted sentinel, sacrifices itself to shield the underlying steel from the corrosive forces of rain, snow, and salt water. Corrosion, the insidious thief that seeks to consume metal, is met with unwavering resistance. The galvanized surface bears the brunt of the attack, preserving the integrity of the steel beneath.

Furthermore, this protective layer boasts impressive durability and longevity. It can withstand extreme temperatures, abrasive conditions, and even the constant bombardment of ultraviolet radiation. This means your outdoor furniture and other galvanized structures will remain rust-free and corrosion-resistant for years to come, providing you with a lasting investment.

In the battle against the elements, hot-dipped galvanizing is an unsurpassed ally, offering a cost-effective and reliable solution to preserving your metal possessions. Like a loyal knight in shining armor, it stands guard, ensuring the longevity and aesthetic appeal of your outdoor haven.